definition

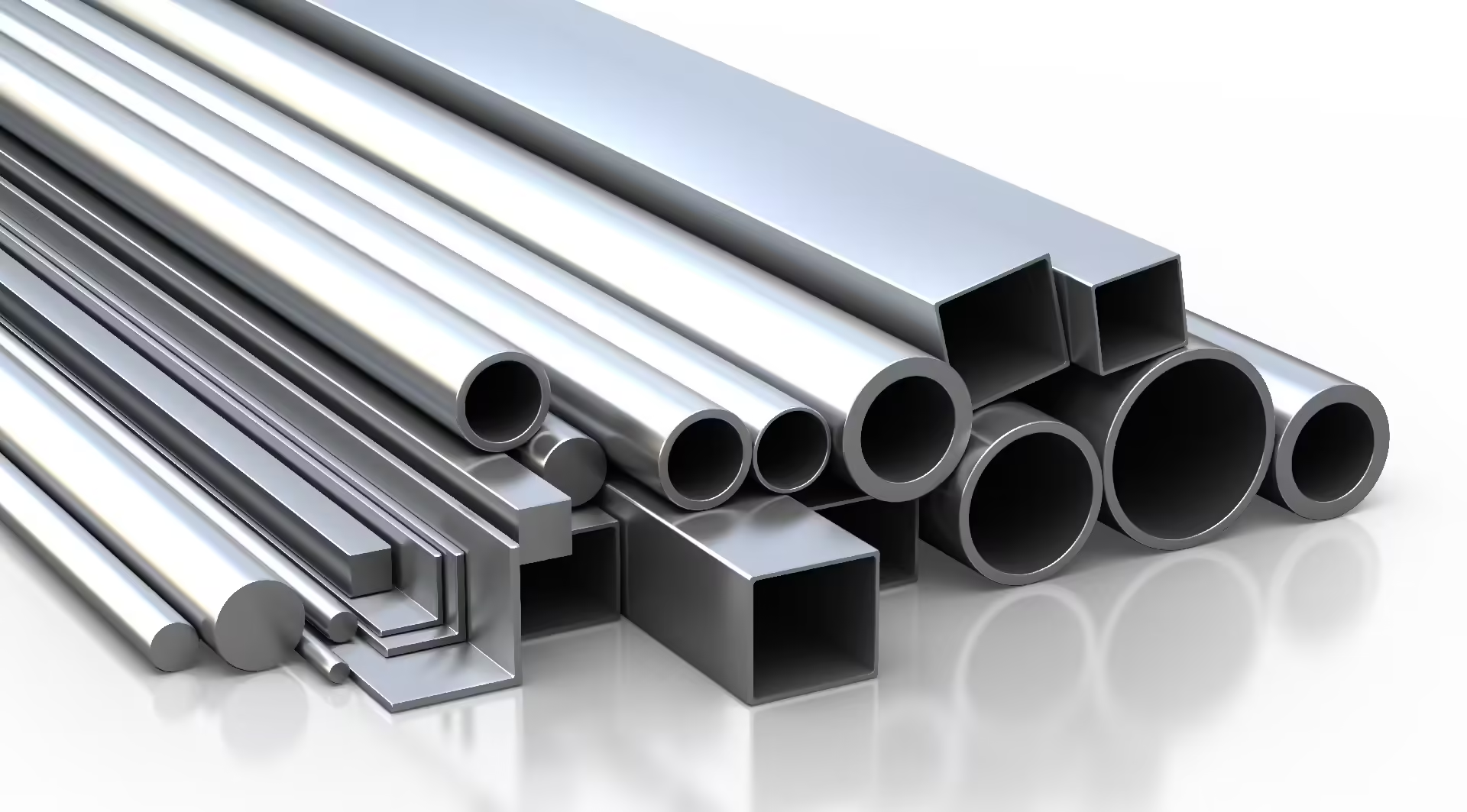

Steel with a hollow section whose length is much greater than its diameter or circumference.

According to the cross-sectional shape, it is divided into round, square, rectangular and special-shaped steel pipes;

according to the material, it is divided into carbon structural steel pipe, low alloy structural steel pipe, alloy steel pipe and composite steel pipe;

according to the use, it is divided into transportation pipeline, engineering structure, Steel pipes for thermal equipment, petrochemical industry, machinery manufacturing, geological drilling, high-pressure equipment, etc.;

according to the production process, they are divided into seamless steel pipes and welded steel pipes, among which seamless steel pipes are divided into hot-rolled and cold-rolled (drawn) There are two types, welded steel pipes are divided into straight seam welded steel pipes and spiral seam welded steel pipes.

production methods

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipes is to thread solid tube blanks or steel ingots into hollow capillary tubes, and then roll them into steel pipes of the required size. The different methods of piercing and rolling pipes constitute different methods of producing seamless steel pipes. The production process of welded steel pipe is to bend the tube blank (steel plate or strip) into a tube shape, and then weld the gaps to form a steel pipe. Different methods of producing welded steel pipes are formed due to the different forming and welding methods used.

Seamless steel pipes are mainly produced by hot rolling. The extrusion method is mainly used to produce low-plasticity high- alloy steel pipes or special-shaped steel pipes and composite metal pipes that are difficult to perforate . old rolling and cold drawing methods can continue to process hot rolled pipes into small diameter and thin wall steel pipes. The welded steel pipe process is simple, the production efficiency is high, the cost is low, and the product variety is expanding day by day.

Seamless steel pipe and welded steel pipe production method

| production method | Basic process | ||

|---|---|---|---|

| wearhole | rolled pipe | ||

| Hot rolling method | Rolling on automatic pipe rolling unit | Round tube blanks are punched on a two-roller punching machine | Rolling with short end on a two-roller mill with feed roller |

| Rolling on the cycle pipe rolling unit | Round steel ingots or tube blanks are punched on a two-roller punching machine | Rolling with long mandrel on cyclic pipe rolling mill with variable cross-section profile | |

| Square or polygonal steel ingots are perforated on a hydraulic press | |||

| Rolling on continuous pipe rolling mill | The round tube blank is punched on a three-roller or two-roller punching machine. | Long mandrel rolling on 7 to 9-stand continuous pipe rolling mill; equipped with tension reducer | |

| Continuous cast billets or square steel ingots are punched on a two-roller pressure punching machine | |||

| Rolled on three-roll pipe mill | Round tube blanks are punched on a two-roller punching machine | Rolling with long mandrel on three-roll cross-rolling mill | |

| The continuous casting billet is punched on a three-roller punching machine | |||

| Rolled on the extension rolling mill | Punching holes on a two-roller punching machine | Rolling with long mandrel on a two-high cross-rolling mill with disc-shaped tension guide rollers | |

| Rolling on planetary tube rolling mill | Cast hollow tube blank | Rolling on planetary tube mill | |

| pipe jacking method | Punch cup-shaped capillary tubes on a hydraulic press | Made on pipe jacking machine | |

| Extrusion method | The tube blank is heated and extruded on the extruder. | Can continue rolling or drawing | |

| Cold rolling method | Hot-rolled pipe material is rolled on a cold-rolled pipe mill | ||

| Cold drawing method | Drawn from hot-rolled or cold-rolled pipe stock on a cold drawing machine | ||

| furnace welding | Chain furnace welding | The heated tube blank is formed into a welded tube mold | Forming and welding at the same time |

| continuous furnace welding | Heated tube blanks are bent on a roll forming welding machine | Forming and welding at the same time | |

| electric welding | resistance welding | Continuous bending on a roll forming machine | Welding on resistance welded pipe machine |

| Arc welding | Press forming on a press or crimping on a roll bending machine (straight seam), continuous bending on a forming machine (spiral seam) | Welding on submerged arc automatic pipe welding machine | |

| Induction welding | Continuous bending on a roll forming machine | Welding on induction pipe welding machine | |

Welded steel pipe

Welded steel pipe, also known as welded pipe, is a type of steel pipe created from steel plates or steel strips that are welded together after being curled and formed. The production process of welded steel pipes is simple, with high production efficiency, a wide range of varieties and specifications, and low equipment investment. However, the overall strength is lower than that of seamless steel pipes. Since the 1930s, with the rapid development of continuous rolling production of high-quality strip steel and the advancement of welding and inspection technology, the quality of welds has continued to improve. Consequently, the varieties and specifications of welded steel pipes have increased day by day, gradually replacing non-welded steel pipes in various fields. Sewing steel pipe. Welded steel pipes are divided into straight seam welded pipes and spiral welded pipes according to the form of the weld.

The production process of straight seam welded pipes is simple, with high production efficiency, low cost, and rapid development. The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. Welded pipes with larger diameters can be produced from narrower billets, and welded pipes with different diameters can also be produced from billets of the same width. However, compared to straight seam pipes of the same length, the weld length is increased by 30%.~The efficiency is 100%, but the production speed is lower. Therefore, smaller diameter welded pipes mostly use straight seam welding, while larger diameter welded pipes mostly use spiral welding.

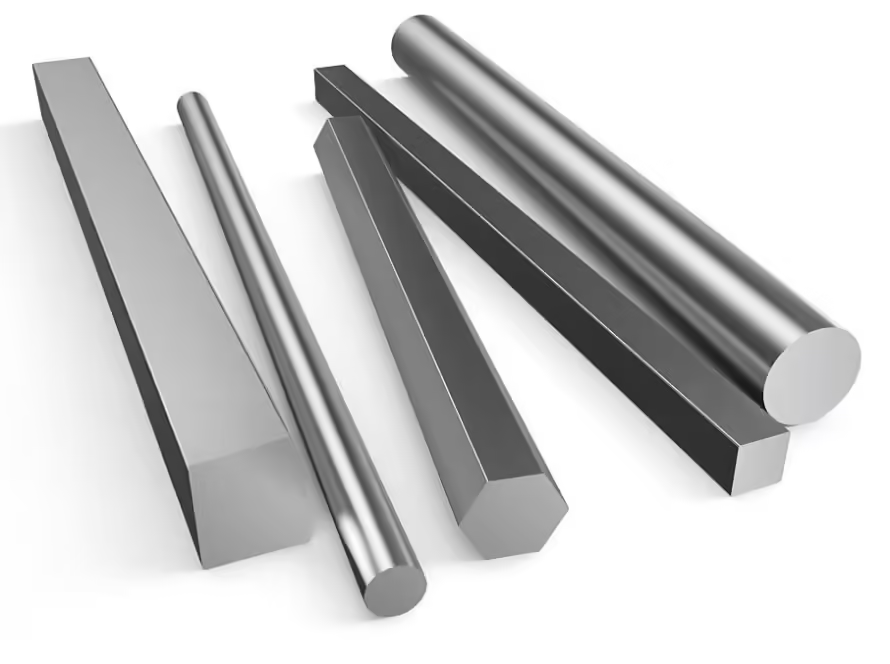

Seamless steel pipe

Seamless steel pipe is a lengthy steel strip with a hollow structure and lacks any seams. These pipes are utilized as conduits for transporting various fluids, including oil, natural gas, coal gas, water, and certain solid materials. In comparison to solid steel forms like round steel, seamless steel pipes exhibit lighter weight while maintaining equivalent bending and torsional strength. They serve as a cost-effective cross-sectional steel variant and find extensive application in the production of structural and mechanical components, such as oil drill pipes, automobile transmission shafts, bicycle racks, and steel scaffolding for construction purposes. The utilization of seamless steel pipes in the fabrication of ring-shaped components enhances material efficiency, streamlines manufacturing processes, and reduces material wastage and processing duration. Steel pipes are categorized into round pipes and specialized pipes based on their cross-sectional area shapes. Circular tubes are preferred for fluid transportation due to their larger circular area when compared to other shapes, enabling efficient fluid conveyance. Moreover, circular cross sections distribute stress uniformly when subjected to internal or external radial pressure, making round pipes the predominant choice. However, round tubes have limitations in plane bending strength compared to square and rectangular tubes, which are commonly employed in agricultural machinery frames, steel and wooden furniture, among other applications. Special-shaped steel pipes with diverse cross-sectional configurations are also necessary to meet specific requirements.