Steel Tube Heat Treating

Steel tube heat treating is a critical process in the manufacturing and engineering industries, aimed at enhancing the mechanical properties of steel tubes. This process involves heating and cooling steel tubes under controlled conditions to achieve desired characteristics such as increased strength, hardness, ductility, and resistance to wear and corrosion. Heat treatment is essential for ensuring that steel tubes meet specific performance requirements for various applications, from construction to automotive and aerospace industries.

What is Steel Tube Heat Treatment?

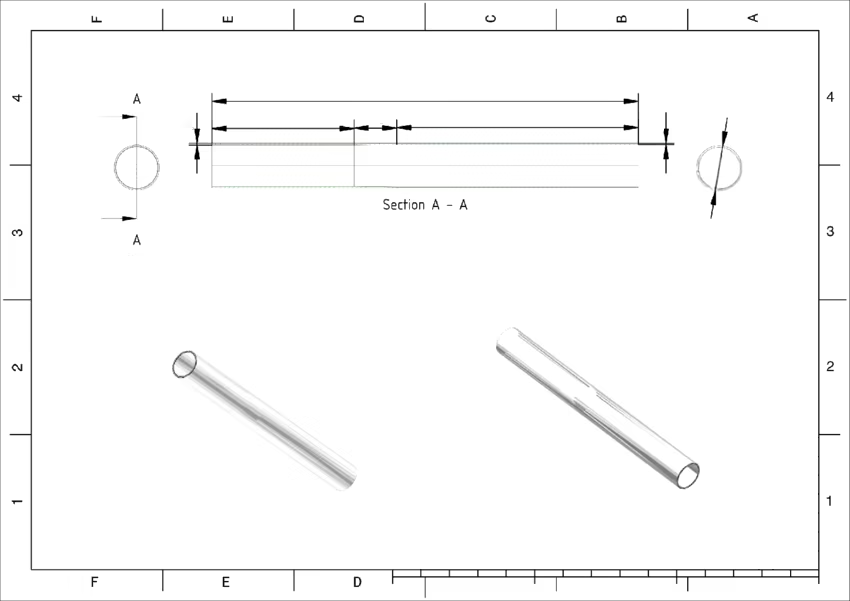

Steel tube heat treatment is a series of thermal and cooling processes applied to steel tubes to alter their physical and mechanical properties without changing their shape. The primary objectives of heat treatment are to improve the material’s performance, extend its service life, and make it suitable for specific applications. The process involves heating the steel to a specific temperature, holding it at that temperature for a certain period, and then cooling it at a controlled rate. The changes in temperature and cooling rates affect the microstructure of the steel, leading to the desired modifications in its properties.

What are the Heat Treatment Methods for Steel Tubes?

Several heat treatment methods are commonly used for steel tubes, each serving a specific purpose:

1. Annealing

Annealing involves heating the steel tube to a specific temperature and then slowly cooling it, usually in a furnace. This process softens the steel, making it more ductile and improving its machinability. Annealing also relieves internal stresses, reduces hardness, and refines the grain structure, enhancing the overall toughness of the steel.

2. Normalizing

Normalizing is similar to annealing but involves heating the steel to a higher temperature and cooling it in air. This method refines the grain structure and improves the uniformity of the microstructure, resulting in enhanced mechanical properties. Normalizing is often used to prepare steel for further heat treatment processes or to restore its original properties after welding or machining.

3. Quenching

Quenching involves heating the steel tube to a high temperature and then rapidly cooling it in water, oil, or another cooling medium. This process increases the hardness and strength of the steel by transforming its microstructure into martensite. However, quenching can also make the steel more brittle, which is why it is often followed by tempering.

4. Tempering

Tempering is performed after quenching to reduce the brittleness of the steel while maintaining its hardness and strength. The steel is reheated to a lower temperature and then cooled at a controlled rate. This process relieves internal stresses and improves the toughness and ductility of the steel, making it more suitable for practical applications.

Which Steel Cannot Be Heat Treated?

Not all steels are suitable for heat treatment. Low-carbon steels, typically containing less than 0.3% carbon, cannot be effectively hardened through heat treatment processes like quenching and tempering. These steels do not have enough carbon content to form martensite, the hard microstructure that results from quenching. As a result, low-carbon steels are often used in applications where high strength and hardness are not critical, and they are typically strengthened through other means, such as cold working.

Conclusion

Steel tube heat treating is an essential process for enhancing the performance and durability of steel tubes. By selecting the appropriate heat treatment method—whether annealing, normalizing, quenching, or tempering—manufacturers can tailor the properties of steel tubes to meet specific requirements. However, it is important to note that not all steels can be heat treated effectively, particularly low-carbon steels, which lack the necessary carbon content for hardening. Understanding the capabilities and limitations of different steel types and heat treatment methods is crucial for optimizing the performance of steel tubes in various industrial applications.