What is a Cold Drawn Tube?

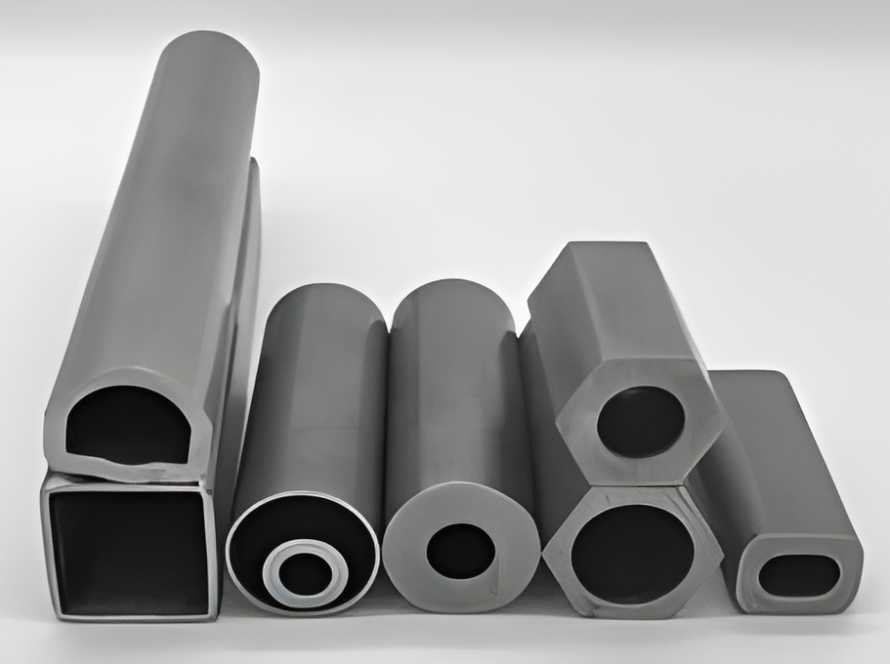

Cold drawn tubes, also known as cold drawn steel pipes, are a type of metal tubing that undergoes a specific manufacturing process to achieve precise dimensions and enhanced mechanical properties. This process involves pulling the tube through a die, which reduces its diameter and wall thickness while improving its surface finish and strength. Cold drawn tubes are widely used in various industries due to their superior quality and performance characteristics.

What is Cold Drawn Steel Pipe?

Cold drawn steel pipes are produced by drawing a steel billet through a series of dies to achieve the desired shape and size. This process is performed at room temperature, which distinguishes it from other methods like hot rolling. The cold drawing process enhances the mechanical properties of the steel, resulting in a product that is stronger, more durable, and has a smoother surface finish compared to other types of steel pipes.

What are the Main Characteristics of Cold Drawn Steel Pipe?

Cold drawn steel pipes exhibit several key characteristics:

-

Precision: The cold drawing process allows for tight tolerances and precise dimensions, making these pipes ideal for applications requiring high accuracy.

-

Surface Finish: The process results in a smooth surface finish, reducing the need for additional machining or finishing operations.

-

Mechanical Properties: Cold drawn steel pipes have improved tensile strength and hardness compared to their hot-rolled counterparts.

-

Dimensional Stability: These pipes maintain their shape and size better under stress, making them suitable for high-pressure applications.

What is the Difference Between Cold Drawn, Hot Rolling, and Cold Rolling?

-

Hot Rolling: This process involves rolling the steel at high temperatures, which makes it easier to shape. However, it results in a rough surface finish and less precise dimensions compared to cold drawing.

-

Cold Rolling: Similar to cold drawing, cold rolling is performed at room temperature. However, it primarily involves compressing the steel between rollers, rather than pulling it through a die. Cold rolling improves surface finish and dimensional accuracy but does not enhance mechanical properties to the same extent as cold drawing.

-

Cold Drawing: As mentioned, this process involves pulling the steel through a die, resulting in superior mechanical properties, precise dimensions, and a smooth surface finish.

What are the Application Fields of Cold Drawn Steel Pipe?

Cold drawn steel pipes are used in a wide range of industries due to their excellent properties:

-

Automotive Industry: Used in the manufacturing of precision components like shock absorbers, steering systems, and engine parts.

-

Aerospace Industry: Utilized for hydraulic systems and structural components that require high strength and precision.

-

Construction: Employed in the production of scaffolding, structural supports, and other construction materials.

-

Oil and Gas: Used in pipelines and drilling equipment due to their ability to withstand high pressure and corrosive environments.

-

Mechanical Engineering: Applied in the production of machinery parts, bearings, and other components that require high precision and strength.

Conclusion

Cold drawn tubes are a vital component in many industries due to their superior mechanical properties, precision, and surface finish. The cold drawing process sets them apart from hot-rolled and cold-rolled products by enhancing strength and dimensional accuracy. Their applications span across automotive, aerospace, construction, oil and gas, and mechanical engineering sectors, highlighting their versatility and importance in modern manufacturing.