Description

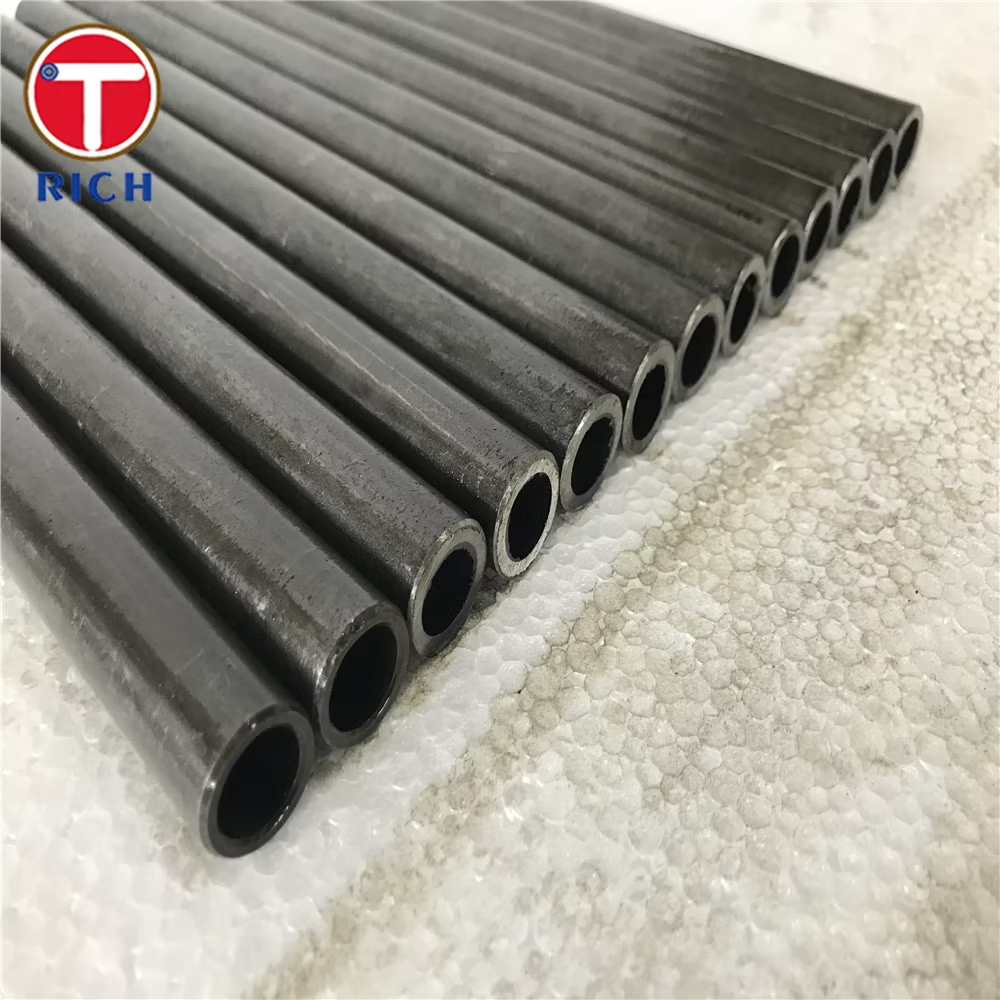

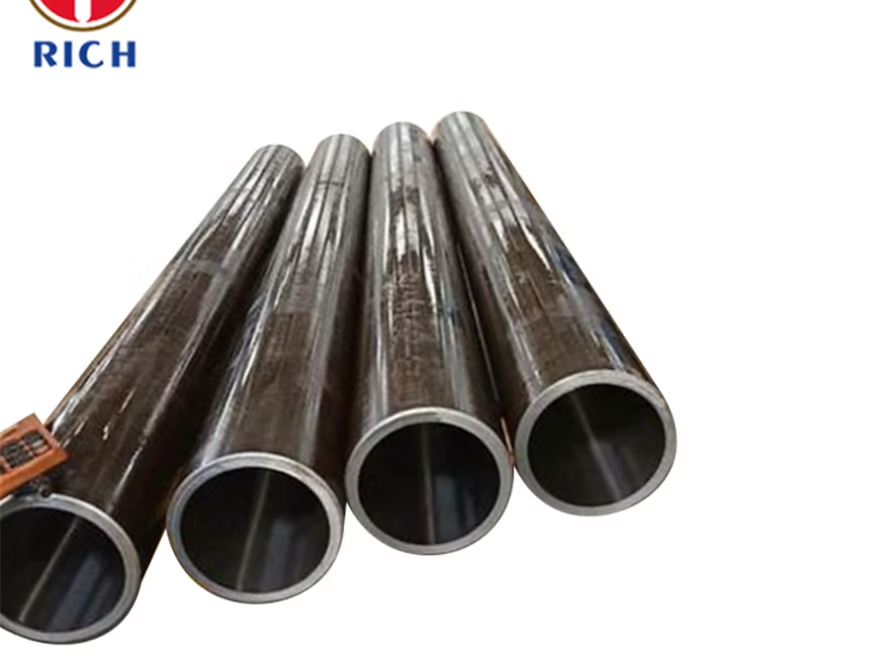

ASTM A210 Grade A-1 and Grade C Heat Exchanger Tubes

Introduction

ASTM A210 is a specification for seamless and welded carbon steel tubes intended for use in heat exchangers, condensers, and similar applications. This article delves into the specifics of ASTM A210 Grade A-1 and Grade C heat exchanger tubes, including their material properties, specifications, key features, chemical composition, mechanical properties, applications, and possible alternative grades.

Material

The ASTM A210 tubes are primarily made from carbon steel, which provides excellent thermal conductivity and mechanical properties suitable for heat exchange applications. The grades A-1 and C differ in their chemical composition and mechanical properties, making them suitable for various operational conditions.

Specification

The ASTM A210 specification outlines the requirements for seamless and welded tubes, including dimensions, tolerances, and testing methods. The specification ensures that the tubes meet the necessary standards for pressure and temperature applications.

Key Features

- High Thermal Conductivity: Ideal for heat exchange applications.

- Corrosion Resistance: Suitable for various environments.

- Versatile Applications: Used in power plants, chemical processing, and oil refineries.

- Seamless and Welded Options: Provides flexibility in manufacturing.

Chemical Composition

| Element | Grade A-1 (%) | Grade C (%) |

|---|---|---|

| Carbon (C) | 0.25 max | 0.30 max |

| Manganese (Mn) | 0.60 – 0.90 | 0.60 – 0.90 |

| Phosphorus (P) | 0.035 max | 0.035 max |

| Sulfur (S) | 0.035 max | 0.035 max |

| Silicon (Si) | 0.10 – 0.40 | 0.10 – 0.40 |

| Chromium (Cr) | 0.40 max | 0.40 max |

| Molybdenum (Mo) | 0.10 max | 0.10 max |

Mechanical Properties

| Property | Grade A-1 | Grade C |

|---|---|---|

| Yield Strength (MPa) | 205 | 240 |

| Tensile Strength (MPa) | 310 | 345 |

| Elongation (%) | 30 | 25 |

| Hardness (HB) | 150 max | 160 max |

Steel Grade

- Grade A-1: Suitable for low-pressure applications and moderate temperatures.

- Grade C: Designed for higher pressure and temperature applications.

Application

ASTM A210 Grade A-1 and Grade C heat exchanger tubes are widely used in:

- Power generation plants

- Chemical processing industries

- Oil and gas refineries

- HVAC systems

- Marine applications

Possible Alternative Grades

While ASTM A210 Grade A-1 and Grade C are popular choices, other grades may be considered based on specific requirements:

- ASTM A192: Seamless carbon steel boiler tubes.

- ASTM A179: Seamless cold-drawn low-carbon steel heat exchanger tubes.

- ASTM A53: Pipe suitable for welding and bending.