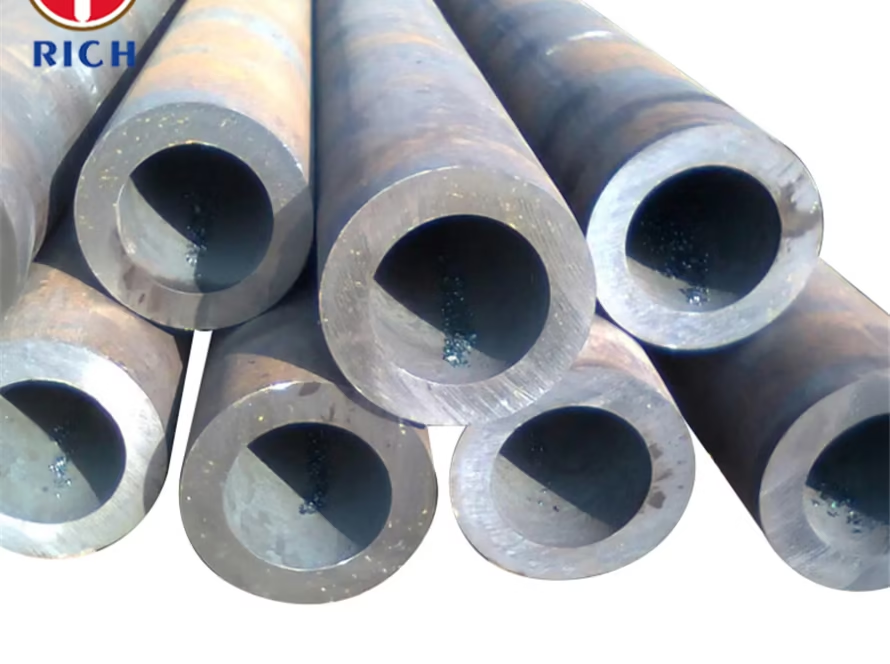

Description

ASTM A106 GrA GrB GrC High Temperature Steel Tube

Material

ASTM A106 is a specification for High Temperature Steel Tube designed for high-temperature service. These pipes are commonly used in industries such as oil and gas, power generation, and petrochemical processing. The specification covers three grades: A, B, and C, each with varying chemical compositions and mechanical properties to suit different applications.

Specification

ASTM A106 High Temperature Steel Tube are manufactured to withstand high temperatures and pressures. The specification ensures that the pipes have the necessary strength, durability, and resistance to corrosion and oxidation. The pipes are available in various sizes and wall thicknesses, making them versatile for different industrial applications.

Key Features

- High Temperature Resistance: Suitable for use in environments with elevated temperatures.

- Seamless Construction: Provides superior strength and uniformity compared to welded pipes.

- Versatility: Available in multiple grades and sizes to meet diverse application needs.

- Corrosion Resistance: Offers good resistance to corrosion and oxidation, extending the service life of the pipes.

Chemical Composition

The chemical composition of ASTM A106 High Temperature Steel Tube varies by grade. Below is a table presenting the typical chemical composition for each grade:

| Element | Grade A (%) | Grade B (%) | Grade C (%) |

|---|---|---|---|

| Carbon (C) | 0.25 max | 0.30 max | 0.35 max |

| Manganese (Mn) | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus (P) | 0.035 max | 0.035 max | 0.035 max |

| Sulfur (S) | 0.035 max | 0.035 max | 0.035 max |

| Silicon (Si) | 0.10 min | 0.10 min | 0.10 min |

Mechanical Properties

The mechanical properties of ASTM A106 High Temperature Steel Tube are crucial for their performance in high-temperature applications. The table below outlines the typical mechanical properties for each grade:

| Property | Grade A | Grade B | Grade C |

|---|---|---|---|

| Tensile Strength (MPa) | 330 min | 415 min | 485 min |

| Yield Strength (MPa) | 205 min | 240 min | 275 min |

| Elongation (%) | 35 min | 30 min | 30 min |

Steel Grade

ASTM A106 pipes are available in three grades: A, B, and C. Each grade is designed to meet specific requirements for strength and temperature resistance. Grade B is the most commonly used due to its balanced properties, making it suitable for a wide range of applications.

Application

ASTM A106 pipes are widely used in industries that require high-temperature and high-pressure piping systems. Common applications include:

- Oil and gas refineries

- Power plants

- Petrochemical facilities

- Boilers and heat exchangers

- Industrial piping systems

Possible Alternative Grades

While ASTM A106 is a popular choice for high-temperature applications, there are alternative grades that may be considered based on specific requirements:

- ASTM A53: Suitable for lower temperature and pressure applications.

- ASTM A333: Designed for low-temperature service.

- ASTM A335: Alloy steel pipes for high-temperature service, offering enhanced strength and corrosion resistance.