Description

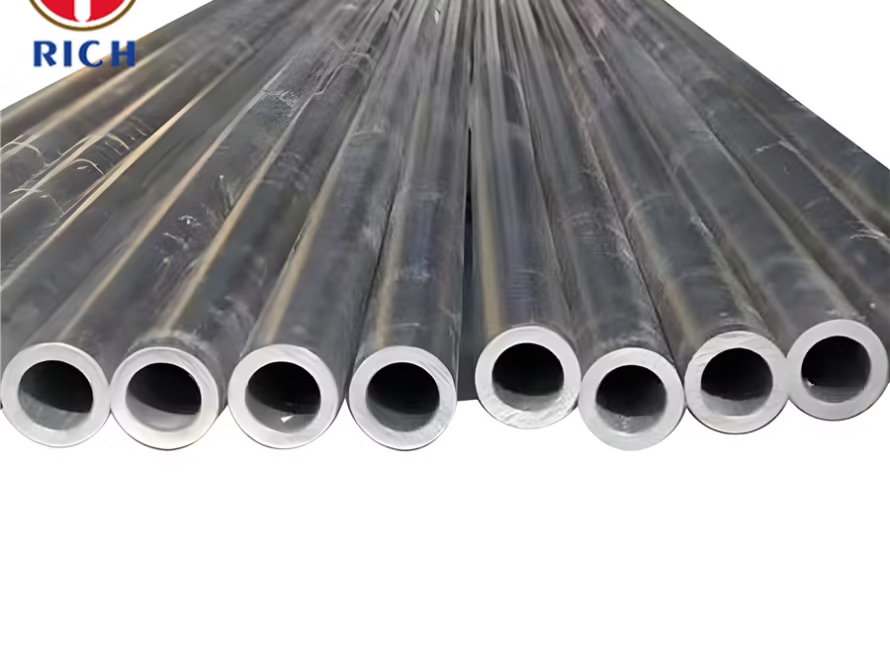

ASTM B829 Inconel 625 Tube For Marine Engineering

Material

Inconel 625 Tube is a nickel-chromium-molybdenum alloy known for its high strength, excellent fabricability, and outstanding corrosion resistance. It is particularly suitable for marine engineering applications due to its ability to withstand harsh environments, including saltwater and high-pressure conditions.

Specification

ASTM B829 is the standard specification for nickel and nickel-cobalt alloy seamless pipe and tube. This specification covers the requirements for Inconel 625 tube, ensuring they meet the necessary standards for quality and performance in demanding applications.

Key Features

- Corrosion Resistance: Exceptional resistance to pitting, crevice corrosion, and intergranular attack.

- High Strength: Maintains strength at elevated temperatures.

- Fabricability: Easily welded and processed using standard techniques.

- Oxidation Resistance: Withstands oxidation at high temperatures.

- Versatility: Suitable for a wide range of applications beyond marine engineering.

Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Iron (Fe) | 5.0 max |

| Columbium (Nb) + Tantalum (Ta) | 3.15 – 4.15 |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Aluminum (Al) | 0.40 max |

| Titanium (Ti) | 0.40 max |

| Carbon (C) | 0.10 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 120 ksi (827 MPa) min |

| Yield Strength | 60 ksi (414 MPa) min |

| Elongation | 30% min |

| Hardness | 30 HRC max |

Steel Grade

Inconel 625 tube is classified under the UNS N06625 designation. It is a non-ferrous alloy, primarily composed of nickel, and is not categorized as a steel grade.

Application

Inconel 625 tube are widely used in marine engineering for applications such as:

- Heat exchangers

- Seawater piping systems

- Offshore oil and gas platforms

- Submarine components

- Marine exhaust systems

Possible Alternative Grades

While Inconel 625 tube is highly suitable for marine applications, alternative grades may be considered based on specific requirements:

- Inconel 718: Offers higher strength at elevated temperatures.

- Hastelloy C276: Provides superior corrosion resistance in more aggressive environments.

- Monel 400: Suitable for less demanding marine applications with excellent corrosion resistance.