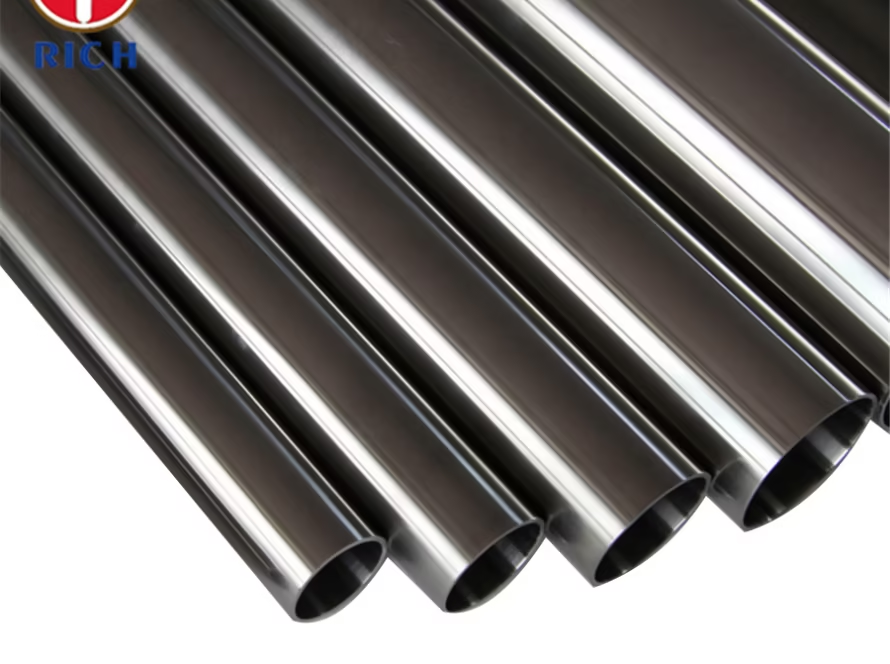

Description

ASTM A268 TP405 Stainless Steel Tubing for General Service

Material Introduction

ASTM A268 covers ferritic stainless steel tubing intended for general service applications, particularly in environments requiring resistance to scaling, corrosion, and oxidation. These grades (TP405, TP410, TP430, TP439, TP444) are widely used in automotive, heat exchanger, and industrial process systems due to their balance of corrosion resistance, thermal stability, and mechanical strength.

Specifications

-

Standard: ASTM A268

-

Grades: TP405, TP410, TP430, TP439, TP444

-

Type: Seamless or Welded Stainless Steel Tubing

-

Condition: As-welded, annealed, or heat-treated

-

Applications: General service, heat exchangers, automotive exhaust systems, boiler tubing, chemical processing equipment.

Chemical Composition of Comparable Grades

| Grade | C (max, %) | Mn (max, %) | P (max, %) | S (max, %) | Si (max, %) | Cr (%) | Ni (%) | Mo (%) | Nb/Ti |

|---|---|---|---|---|---|---|---|---|---|

| TP405 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 11.5–14.5 | – | – | Al/Ti stabilizer |

| TP410 | 0.15 | 1.00 | 0.040 | 0.030 | 1.00 | 11.5–13.5 | – | – | – |

| TP430 | 0.12 | 1.00 | 0.040 | 0.030 | 1.00 | 16.0–18.0 | – | – | – |

| TP439 | 0.03 | 1.00 | 0.040 | 0.030 | 1.00 | 17.0–19.0 | – | – | Ti/Nb stabilized |

| TP444 | 0.025 | 1.00 | 0.040 | 0.030 | 1.00 | 17.5–19.5 | – | 1.75–2.50 | Nb/Ti |

Mechanical Properties of Comparable Grades

| Grade | Tensile Strength (MPa) | Yield Strength (0.2% offset, MPa) | Elongation (%) | Hardness (HB max) |

|---|---|---|---|---|

| TP405 | ≥ 380 | ≥ 205 | ≥ 20 | 183 |

| TP410 | ≥ 450 | ≥ 275 | ≥ 20 | 217 |

| TP430 | ≥ 415 | ≥ 205 | ≥ 22 | 183 |

| TP439 | ≥ 415 | ≥ 205 | ≥ 20 | 183 |

| TP444 | ≥ 440 | ≥ 275 | ≥ 20 | 217 |

Key Features

-

TP405: Aluminum/titanium stabilized, resists scaling, good weldability, used in heat exchangers and automotive parts.

-

TP410: Martensitic stainless steel, higher strength, moderate corrosion resistance, suitable for high-stress parts.

-

TP430: Ferritic stainless steel, good corrosion resistance in mildly aggressive environments, cost-effective.

-

TP439: Titanium/niobium stabilized, excellent resistance to intergranular corrosion, improved weldability.

-

TP444: Higher molybdenum content, excellent resistance to chloride stress corrosion cracking and pitting.

Standards Compliance

-

ASTM: ASTM A268 (Ferritic Stainless Steel Tubes for General Service)

-

EN: EN 10217-7 (Welded stainless steel tubes for pressure purposes)

-

JIS: JIS G3463 (Stainless steel boiler and heat exchanger tubes)

-

GB: GB/T 14976 (Stainless steel seamless tubes for fluid transport)

-

GOST: GOST 9941 (Seamless stainless steel tubes)

Application Fields

-

Automotive Industry: Exhaust systems, mufflers, catalytic converter shells (TP405, TP409, TP439).

-

Heat Exchangers: Power plants, chemical plants, refinery heaters (TP430, TP444).

-

Industrial Equipment: Food processing, petrochemical plants, boiler tubes.

-

Construction: Architectural cladding and structural tubing.

-

Energy Sector: Superheater tubes, condenser tubing, desalination equipment.