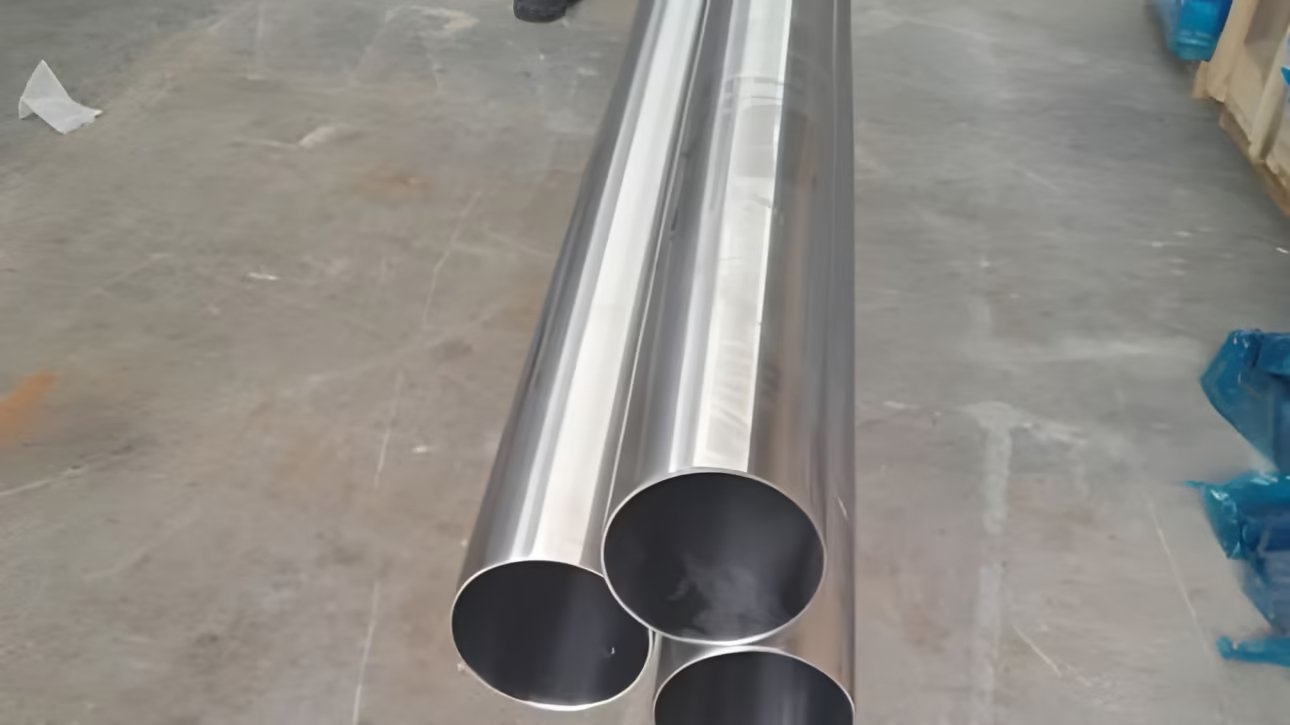

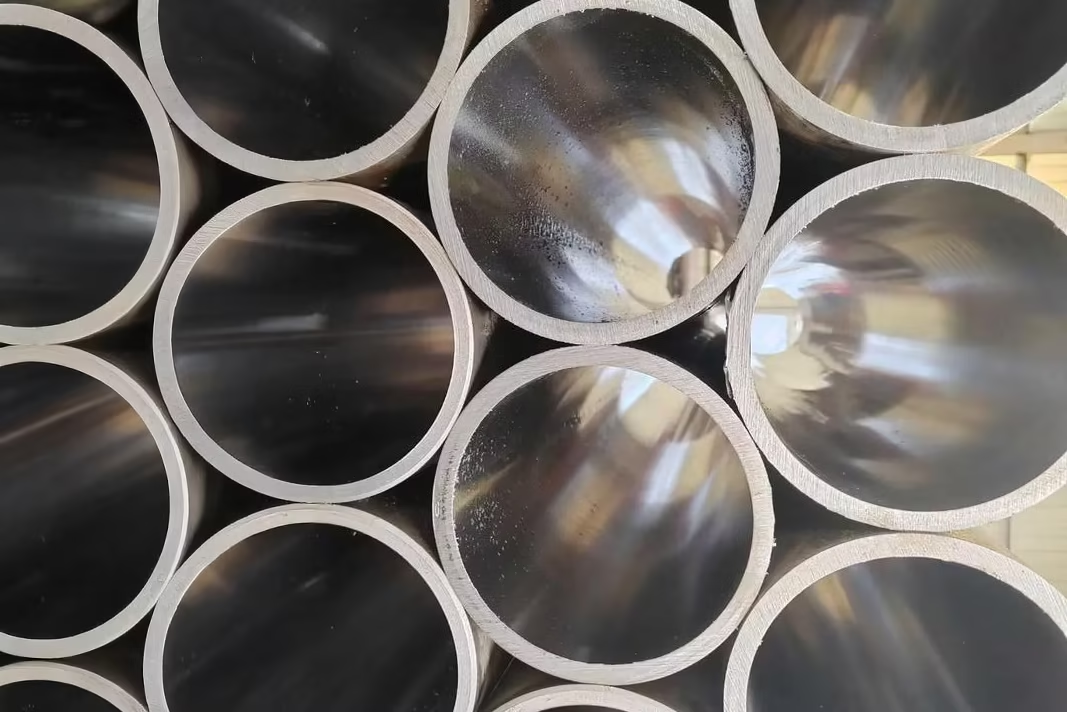

1. What exactly is duplex stainless steel pipe?

Duplex stainless steel Pipe is a type of stainless steel whose internal structure is roughly half austenite and half ferrite. This “two-phase” microstructure is why it’s called duplex. In pipe form, that structure gives you:

About twice the strength of common austenitic grades like 304/316

…