Description

ASTM A500 Gr.A, Gr.B, Gr.C, Gr.D Cold Formed Steel Tube

Introduction

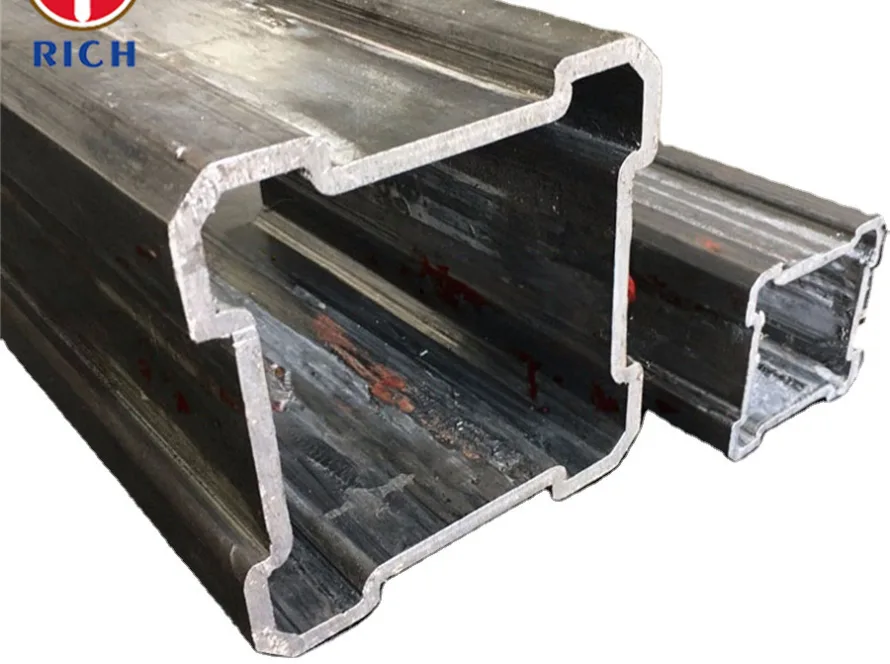

ASTM A500 cold formed steel tube is a standard specification for cold-formed welded and seamless carbon steel structural tubing in round, square, and rectangular shapes. This specification covers four different grades of carbon steel tubing, namely Gr.A, Gr.B, Gr.C, and Gr.D. Each grade has specific chemical composition and mechanical properties, making them suitable for various applications in structural engineering and construction.

Material and Specification

The ASTM A500 Gr.A, Gr.B, Gr.C, and Gr.D cold formed steel tube are manufactured using carbon steel. The tubes are produced by either seamless or welded methods and are available in round, square, and rectangular shapes. The dimensions and tolerances of these tubes are specified in the ASTM A500 standard.

Key Features

- Cold-formed design: The tubes are formed at ambient temperature, resulting in improved dimensional accuracy and surface finish.

- High strength: The carbon steel material used in these tubes provides excellent strength and durability.

- Wide range of sizes: ASTM A500 tubes are available in various sizes and shapes to suit different structural applications.

- Good weldability: These tubes can be easily welded using common welding techniques.

- Corrosion resistance: The carbon steel material used in these tubes has good resistance to corrosion, ensuring long-lasting performance.

Chemical Composition

| Element | Gr.A (%) | Gr.B (%) | Gr.C (%) | Gr.D (%) |

|---|---|---|---|---|

| Carbon | 0.26 | 0.23 | 0.23 | 0.27 |

| Manganese | 1.35 | 1.35 | 1.35 | 1.35 |

| Phosphorus | 0.035 | 0.035 | 0.035 | 0.035 |

| Sulfur | 0.035 | 0.035 | 0.035 | 0.035 |

Mechanical Properties

| Property | Gr.A | Gr.B | Gr.C | Gr.D |

|---|---|---|---|---|

| Tensile Strength (MPa) | 310 | 400 | 425 | 400 |

| Yield Strength (MPa) | 230 | 315 | 345 | 250 |

| Elongation (%) | 25 | 23 | 21 | 23 |

| Hardness (HRB) | 48 | 58 | 62 | 58 |

Steel Grade

The ASTM A500 standard defines four different steel grades for cold-formed steel tubes: Gr.A, Gr.B, Gr.C, and Gr.D. These grades are differentiated based on their chemical composition and mechanical properties.

Application

ASTM A500 Gr.A, Gr.B, Gr.C, and Gr.D cold formed steel tube find applications in various structural engineering and construction projects. Some common applications include:

- Building frames and structures

- Bridges

- Highway guardrails

- Towers and poles

- Industrial equipment supports

- Infrastructure projects

Possible Alternative Grades

While ASTM A500 Gr.A, Gr.B, Gr.C, and Gr.D cold formed steel tube are widely used, there are alternative grades available for specific applications. Some possible alternative grades include ASTM A513, ASTM A1085, and ASTM A252. These grades may offer different chemical compositions, mechanical properties, or dimensional tolerances, making them suitable for specific requirements.