Description

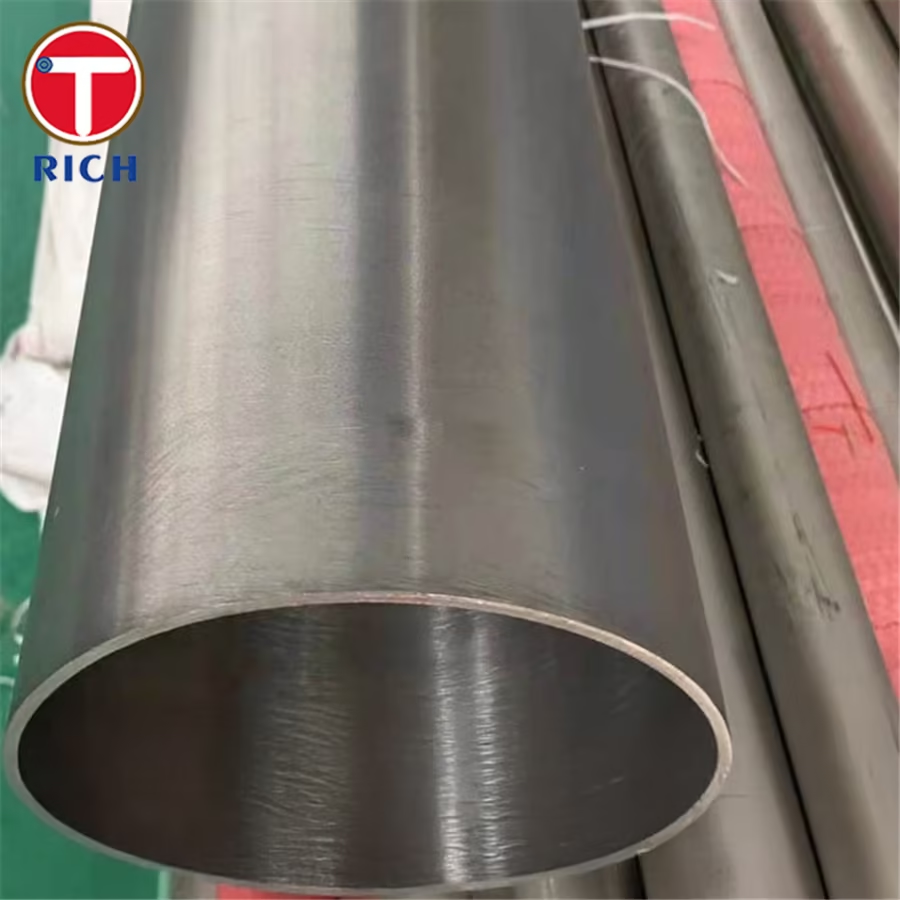

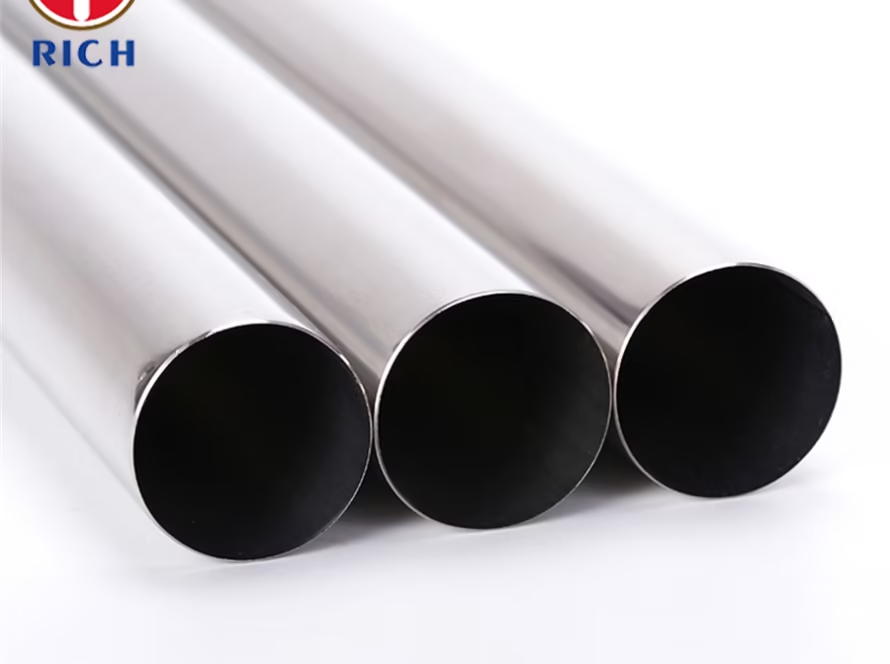

ASTM B622 Hastelloy C276 Pipe For Petrochemical

Material

Hastelloy C276 is a nickel-molybdenum-chromium superalloy known for its exceptional corrosion resistance in a wide range of severe environments. It is particularly effective in resisting pitting, crevice corrosion, and stress corrosion cracking. This makes it an ideal choice for the petrochemical industry, where harsh conditions are common.

Specification

ASTM B622 is the standard specification for seamless nickel and nickel-cobalt alloy pipe and tube. The specification covers Hastelloy C276 pipe, ensuring they meet the necessary mechanical and chemical requirements for use in demanding applications.

Key Features

- Corrosion Resistance: Outstanding resistance to a variety of chemical environments, including oxidizing and reducing conditions.

- Temperature Stability: Maintains mechanical properties across a wide temperature range.

- Versatility: Suitable for a variety of applications due to its robust performance in harsh conditions.

- Durability: High resistance to stress corrosion cracking and pitting.

Chemical Composition

The chemical composition of Hastelloy C276 pipe is crucial for its performance. Below is a table detailing its typical composition:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | 2.5 max |

| Manganese (Mn) | 1.0 max |

| Vanadium (V) | 0.35 max |

| Silicon (Si) | 0.08 max |

| Carbon (C) | 0.01 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

Mechanical Properties

The mechanical properties of Hastelloy C276 are essential for its application in high-stress environments. The table below outlines these properties:

| Property | Value |

|---|---|

| Tensile Strength | 100 ksi (690 MPa) |

| Yield Strength (0.2% offset) | 41 ksi (283 MPa) |

| Elongation | 40% |

| Hardness (Rockwell B) | 95 max |

Steel Grade

Hastelloy C276 is often referred to by its UNS number, N10276. It is a part of the Hastelloy family of alloys, which are known for their high performance in corrosive environments.

Application

Hastelloy C276 pipe are widely used in the petrochemical industry for:

- Chemical processing equipment

- Piping systems for corrosive environments

- Heat exchangers

- Reactors and pressure vessels

- Flue gas desulfurization systems

Possible Alternative Grades

While Hastelloy C276 is highly effective, there are alternative grades that might be considered based on specific requirements:

- Hastelloy C22: Offers similar corrosion resistance with improved resistance to oxidizing media.

- Inconel 625: Known for its high strength and excellent corrosion resistance, particularly in seawater applications.

- Monel 400: A nickel-copper alloy with good corrosion resistance in a wide range of media, but less resistant than Hastelloy C276.