Description

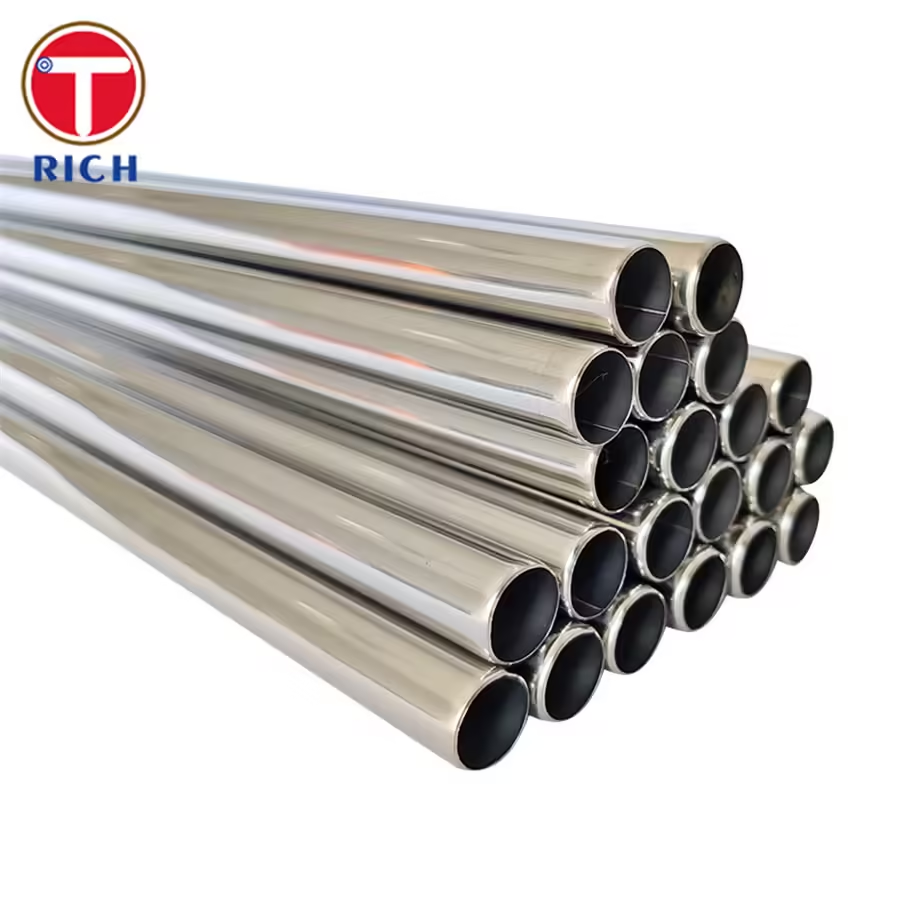

ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube

Material and Specification

The ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube is a high-quality stainless steel tube designed specifically for heat exchanger applications. It is manufactured according to the ASTM A249 standard, which outlines the requirements for welded austenitic steel boiler, superheater, heat exchanger, and condenser tubes.

The material used in this stainless steel tube is a low-carbon variation of the popular 304 grade stainless steel. The TP304, TP304L, TP304H, TP310S, and TP310H designations refer to specific variations of the stainless steel alloy, each with its own unique properties and characteristics.

Key Features

The ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube offers several key features that make it an excellent choice for heat exchanger applications:

-

Corrosion Resistance: The stainless steel alloy used in this tube provides excellent resistance to corrosion, making it suitable for use in various environments, including those with high temperatures and corrosive substances.

-

High Strength: The tube exhibits high strength and durability, ensuring long-lasting performance even under extreme operating conditions.

-

Heat Resistance: The stainless steel alloy used in this tube has excellent heat resistance properties, making it capable of withstanding high temperatures without deformation or degradation.

-

Weldability: The tube is easily weldable, allowing for easy fabrication and installation in heat exchanger systems.

Chemical Composition

The chemical composition of the ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube is as follows:

| Element | TP304 | TP304L | TP304H | TP310S | TP310H |

|---|---|---|---|---|---|

| Carbon | 0.08 | 0.035 | 0.04-0.10 | 0.08 | 0.04-0.10 |

| Manganese | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 |

| Phosphorus | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| Sulfur | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 |

| Silicon | 0.75 | 0.75 | 0.75 | 1.00 | 1.00 |

| Chromium | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | 24.0-26.0 | 24.0-26.0 |

| Nickel | 8.0-11.0 | 8.0-12.0 | 8.0-12.0 | 19.0-22.0 | 19.0-22.0 |

| Nitrogen | – | – | – | – | – |

Mechanical Properties

The mechanical properties of the ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube are as follows:

| Property | TP304 | TP304L | TP304H | TP310S | TP310H |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | ≥515 | ≥485 | ≥515 | ≥515 | ≥515 |

| Yield Strength (MPa) | ≥205 | ≥170 | ≥205 | ≥205 | ≥205 |

| Elongation (%) | ≥35 | ≥35 | ≥35 | ≥35 | ≥35 |

| Hardness (HB) | ≤192 | ≤192 | ≤192 | ≤187 | ≤187 |

Steel Grade

The steel grades covered by the ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube are as follows:

-

TP304: This grade is a low-carbon variation of the popular 304 stainless steel, offering excellent corrosion resistance and high strength.

-

TP304L: This grade has a lower carbon content than TP304, making it suitable for applications where welding is required.

-

TP304H: This grade has a higher carbon content than TP304, providing improved high-temperature strength and creep resistance.

-

TP310S: This grade contains higher amounts of chromium and nickel, offering superior corrosion resistance and high-temperature strength.

-

TP310H: This grade is a high-carbon variation of TP310S, designed for enhanced high-temperature strength and resistance to oxidation.

Application

The ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube is widely used in various heat exchanger applications, including:

- Power generation plants

- Chemical and petrochemical industries

- Food processing and beverage industries

- Pharmaceutical industries

- HVAC systems

- Oil and gas refineries

Its excellent corrosion resistance, high strength, and heat resistance make it an ideal choice for transferring heat between two fluids while maintaining the integrity of the system.

Possible Alternative Grades

While the ASTM A249 TP304 TP304L TP304H TP310S TP310H Heat Exchanger Stainless Steel Tube offers excellent performance, there are alternative grades available for specific requirements. Some possible alternative grades include:

-

TP316: This grade offers improved corrosion resistance, particularly in environments with chloride ions, making it suitable for marine applications.

-

TP321: This grade contains titanium, providing enhanced resistance to intergranular corrosion and high-temperature strength.

-

TP347: This grade contains niobium, offering improved resistance to sensitization and intergranular corrosion at high temperatures.