Description

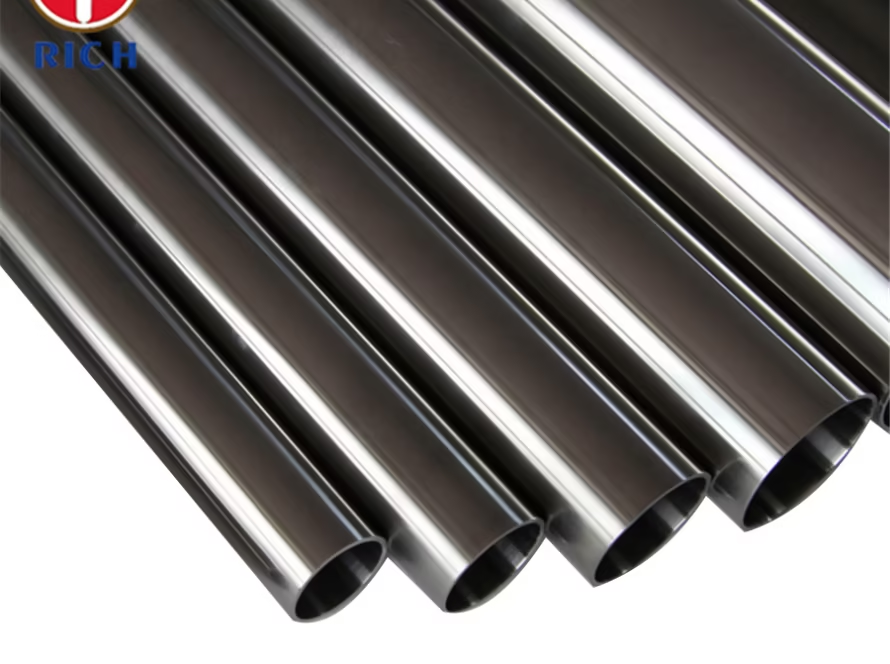

GB/T 13296 12Cr18Ni9 06Cr19Ni10 022Cr19Ni10 07Cr19Ni10 06Cr19Ni10N Heat Exchanger Stainless Steel Tube

Material

The GB/T 13296 Heat Exchanger Stainless Steel Tube standard specifies the requirements for stainless steel tubes used in heat exchangers. The primary grades covered under this standard include 12Cr18Ni9, 06Cr19Ni10, 022Cr19Ni10, 07Cr19Ni10, and 06Cr19Ni10N. These materials are known for their excellent corrosion resistance, high strength, and good thermal conductivity, making them suitable for various industrial applications.

Specification

The specification outlines the dimensions, tolerances, and mechanical properties of the stainless steel tubes. The Heat Exchanger Stainless Steel Tube are typically produced in various sizes and wall thicknesses to meet specific application requirements.

Key Features

- Corrosion Resistance: Excellent resistance to oxidation and corrosion in various environments.

- High Strength: Maintains strength at elevated temperatures.

- Good Fabricability: Easily fabricated into various shapes and sizes.

- Thermal Conductivity: Efficient heat transfer properties.

Chemical Composition

The following table presents the chemical composition of the specified stainless steel grades:

| Steel Grade | C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | Ni (%) | N (%) |

|---|---|---|---|---|---|---|---|---|

| 12Cr18Ni9 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 17.0-19.0 | 8.0-10.0 | – |

| 06Cr19Ni10 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0-18.0 | 9.0-11.0 | – |

| 022Cr19Ni10 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0-18.0 | 9.0-11.0 | 0.10-0.20 |

| 07Cr19Ni10 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0-18.0 | 9.0-11.0 | – |

| 06Cr19Ni10N | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0-18.0 | 9.0-11.0 | 0.10-0.20 |

Mechanical Properties

The following table summarizes the mechanical properties of the specified stainless steel grades:

| Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| 12Cr18Ni9 | ≥205 | ≥520 | ≥40 | ≤187 |

| 06Cr19Ni10 | ≥205 | ≥520 | ≥40 | ≤187 |

| 022Cr19Ni10 | ≥205 | ≥520 | ≥40 | ≤187 |

| 07Cr19Ni10 | ≥205 | ≥520 | ≥40 | ≤187 |

| 06Cr19Ni10N | ≥205 | ≥520 | ≥40 | ≤187 |

Steel Grade

The steel grades specified in GB/T 13296 Heat Exchanger Stainless Steel Tube are primarily austenitic stainless steels, which are characterized by their high chromium and nickel content. These grades are widely used in applications requiring high corrosion resistance and good mechanical properties.

Application

The stainless steel tubes produced under this standard are commonly used in:

- Heat exchangers

- Boilers

- Pressure vessels

- Chemical processing equipment

- Oil and gas industry applications

Possible Alternative Grades

While the specified grades are widely used, alternative grades may also be considered based on specific application requirements. Some possible alternatives include:

- AISI 304: Similar to 06Cr19Ni10, widely used for its good corrosion resistance.

- AISI 316: Offers better corrosion resistance than 304, suitable for marine environments.

- AISI 321: Provides improved high-temperature stability and resistance to intergranular corrosion.