Description

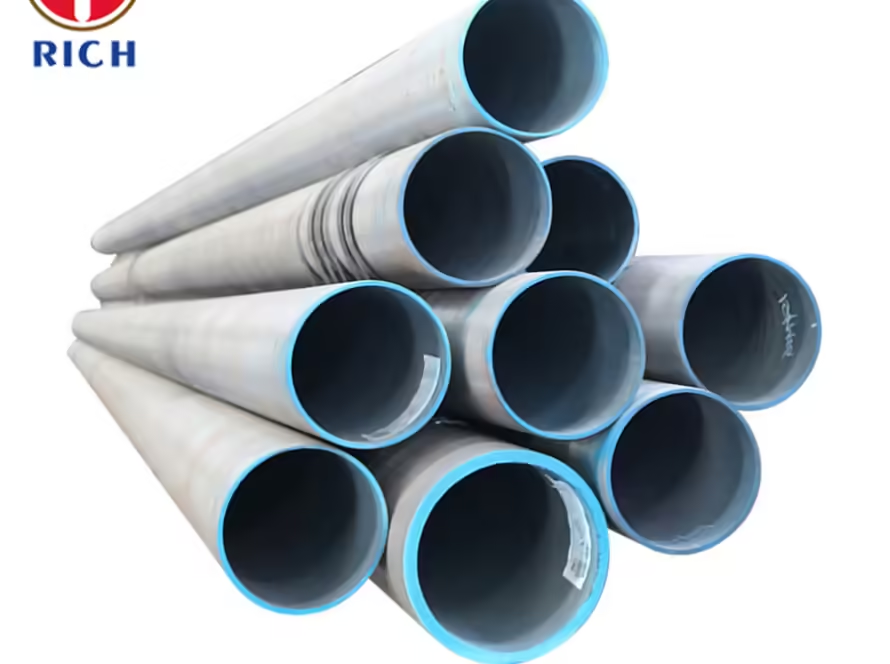

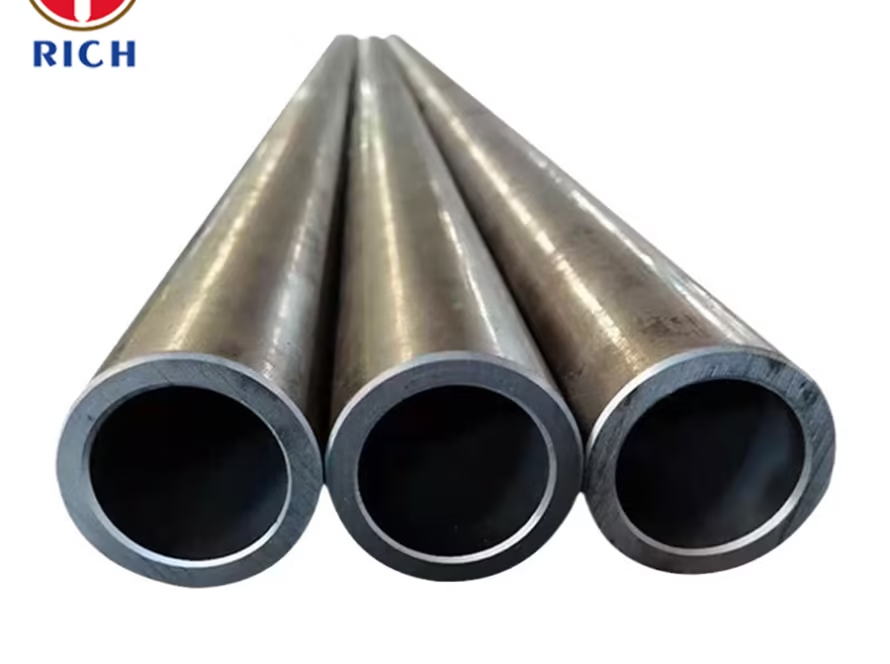

GB/T 17396 30MnNbRE Hot-rolled Seamless Steel Tubes

Introduction

GB/T 17396 is a Chinese national standard that specifies the requirements for hot-rolled seamless steel tubes made of 27SiMn and 30MnNbRE steel grades. These tubes are widely used in various industries due to their excellent mechanical properties and high resistance to corrosion. This article provides an overview of the material, specification, key features, chemical composition, mechanical properties, steel grade, application, and possible alternative grades for GB/T 17396 27SiMn 30MnNbRE hot-rolled seamless steel tubes.

Material and Specification

GB/T 17396 covers two steel grades: 27SiMn and 30MnNbRE. These grades are specifically designed for hot-rolled seamless steel tubes. The standard specifies the dimensions, tolerances, appearance, weight, and technical requirements for these tubes. It also outlines the testing methods and inspection rules to ensure the quality of the final product.

Key Features

The key features of GB/T 17396 27SiMn 30MnNbRE hot-rolled seamless steel tubes include:

- High strength: These tubes exhibit excellent mechanical properties, making them suitable for applications that require high strength and durability.

- Good weldability: The steel grades used in these tubes have good weldability, allowing for easy fabrication and joining.

- Corrosion resistance: The tubes possess high resistance to corrosion, making them suitable for use in harsh environments.

- Seamless construction: The hot-rolled seamless manufacturing process ensures a smooth and uniform surface finish, enhancing the overall performance of the tubes.

Chemical Composition

| Element | 27SiMn Composition (%) | 30MnNbRE Composition (%) |

|---|---|---|

| Carbon (C) | 0.24-0.32 | 0.26-0.34 |

| Silicon (Si) | 1.10-1.40 | 0.20-0.40 |

| Manganese (Mn) | 1.10-1.40 | 0.80-1.10 |

| Phosphorus (P) | ≤0.035 | ≤0.030 |

| Sulfur (S) | ≤0.035 | ≤0.030 |

| Chromium (Cr) | – | ≤0.25 |

| Nickel (Ni) | – | ≤0.25 |

| Copper (Cu) | – | ≤0.25 |

| Niobium (Nb) | – | 0.015-0.045 |

| Vanadium (V) | – | ≤0.05 |

| Aluminum (Al) | – | ≤0.03 |

| Nitrogen (N) | – | ≤0.012 |

Mechanical Properties

| Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 27SiMn | ≥980 | ≥835 | ≥12 |

| 30MnNbRE | ≥980 | ≥835 | ≥12 |

Steel Grade

The steel grades used in GB/T 17396 27SiMn 30MnNbRE hot-rolled seamless steel tubes are 27SiMn and 30MnNbRE. These grades are carefully selected to provide the desired mechanical properties and corrosion resistance required for various applications.

Application

GB/T 17396 27SiMn 30MnNbRE hot-rolled seamless steel tubes find applications in a wide range of industries, including:

- Oil and gas exploration: These tubes are used in drilling operations and oil well completion.

- Mechanical engineering: They are utilized in the manufacturing of machinery parts, such as cylinders, pistons, and hydraulic systems.

- Construction: The tubes are employed in the construction of high-strength structures, such as bridges and buildings.

- Automotive industry: They are used in the production of automobile components, including chassis and suspension systems.

Possible Alternative Grades

While GB/T 17396 specifies the use of 27SiMn and 30MnNbRE steel grades, there are alternative grades available in other international standards. Some possible alternative grades include ASTM A519 4130, DIN 2391 ST52, and JIS G3445 STKM 13C. These grades may have similar chemical compositions and mechanical properties, providing alternative options for specific applications.