Description

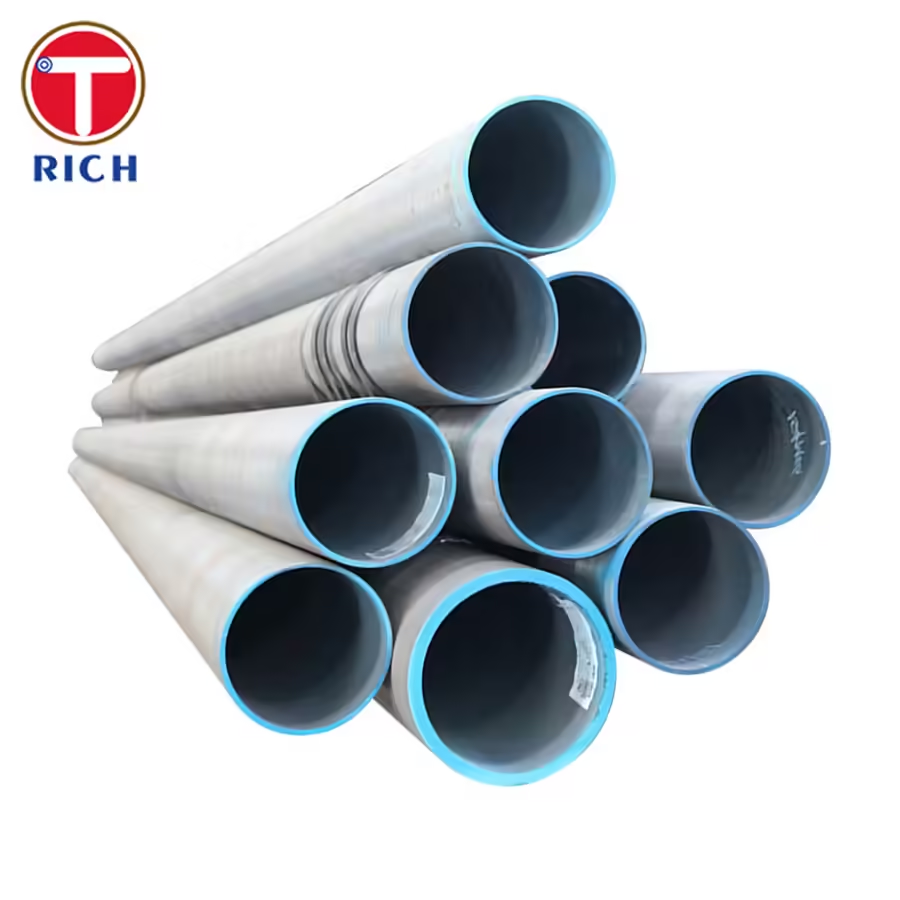

GOST 8732-78 20Ch 40Ch 15ChM 30ChMA Hot Working Steel Tube

Introduction

GOST 8732-78 is a Russian standard that specifies the requirements for hot working steel tubes made from various grades of steel. This article will provide an overview of the material, specification, key features, chemical composition, mechanical properties, steel grades, applications, and possible alternative grades of GOST 8732-78 20Ch, 40Ch, 15ChM, and 30ChMA hot working steel tubes.

Material and Specification

GOST 8732-78 covers hot working steel tubes with an outer diameter ranging from 32 to 168 mm and a wall thickness of 2.9 to 8.0 mm. These tubes are manufactured through hot rolling or hot extrusion processes. The material grades specified in this standard include 20Ch, 40Ch, 15ChM, and 30ChMA.

Key Features

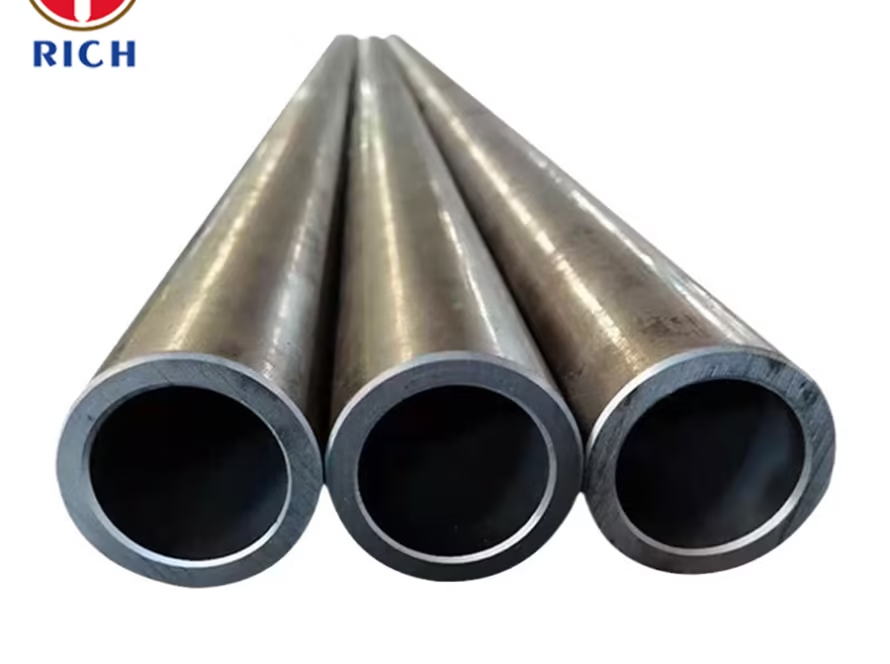

The key features of GOST 8732-78 hot working steel tubes are as follows:

- High heat resistance: These tubes are designed to withstand high temperatures, making them suitable for applications in industries such as oil and gas, power generation, and chemical processing.

- Excellent mechanical properties: GOST 8732-78 steel tubes exhibit good strength, toughness, and ductility, ensuring their reliability and durability in demanding environments.

- Versatility: The standard covers a range of steel grades, allowing for various applications and providing options for different mechanical and chemical requirements.

Chemical Composition

| Steel Grade | Chemical Composition (%) |

|---|---|

| 20Ch | C: 0.17-0.24, Mn: 0.40-0.80, Si: 0.17-0.37, S: ≤0.035, P: ≤0.035 |

| 40Ch | C: 0.37-0.44, Mn: 0.50-0.80, Si: 0.17-0.37, S: ≤0.035, P: ≤0.035 |

| 15ChM | C: 0.12-0.18, Mn: 0.40-0.70, Si: 0.17-0.37, S: ≤0.035, P: ≤0.035, Cr: 0.80-1.10, Mo: 0.15-0.25 |

| 30ChMA | C: 0.27-0.34, Mn: 0.40-0.70, Si: 0.17-0.37, S: ≤0.035, P: ≤0.035, Cr: 0.80-1.10, Mo: 0.15-0.25 |

Mechanical Properties

| Steel Grade | Mechanical Properties |

|---|---|

| 20Ch | Tensile Strength: ≥520 MPa, Yield Strength: ≥245 MPa, Elongation: ≥22% |

| 40Ch | Tensile Strength: ≥620 MPa, Yield Strength: ≥390 MPa, Elongation: ≥20% |

| 15ChM | Tensile Strength: ≥590 MPa, Yield Strength: ≥390 MPa, Elongation: ≥20% |

| 30ChMA | Tensile Strength: ≥590 MPa, Yield Strength: ≥390 MPa, Elongation: ≥20% |

Steel Grade and Application

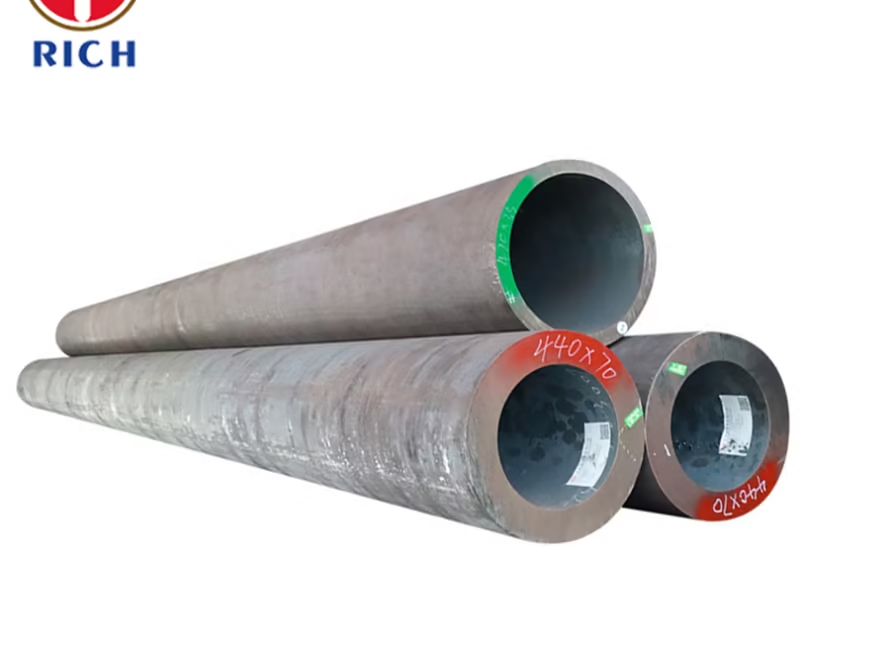

The steel grades specified in GOST 8732-78 have different applications based on their mechanical properties and chemical composition. Here are the steel grades and their typical applications:

- 20Ch: Used in the production of pipelines, boiler tubes, and heat exchangers.

- 40Ch: Suitable for manufacturing parts subjected to high mechanical stress, such as shafts, gears, and axles.

- 15ChM: Used in the production of parts requiring high strength and toughness, such as crankshafts, connecting rods, and turbine blades.

- 30ChMA: Suitable for manufacturing parts subjected to high temperatures and mechanical stress, such as furnace components, heat-resistant containers, and exhaust systems.

Possible Alternative Grades

While GOST 8732-78 specifies the aforementioned steel grades, there are alternative grades available in other international standards. Some possible alternative grades include ASTM A519 1020, DIN 2391 ST52, and JIS G3445 STKM 11A. These alternative grades may have similar chemical compositions and mechanical properties, allowing for substitution in certain applications.