Description

Low Alloy Steel Pipe ASTM A423: Material, Specification, Key Features

Introduction

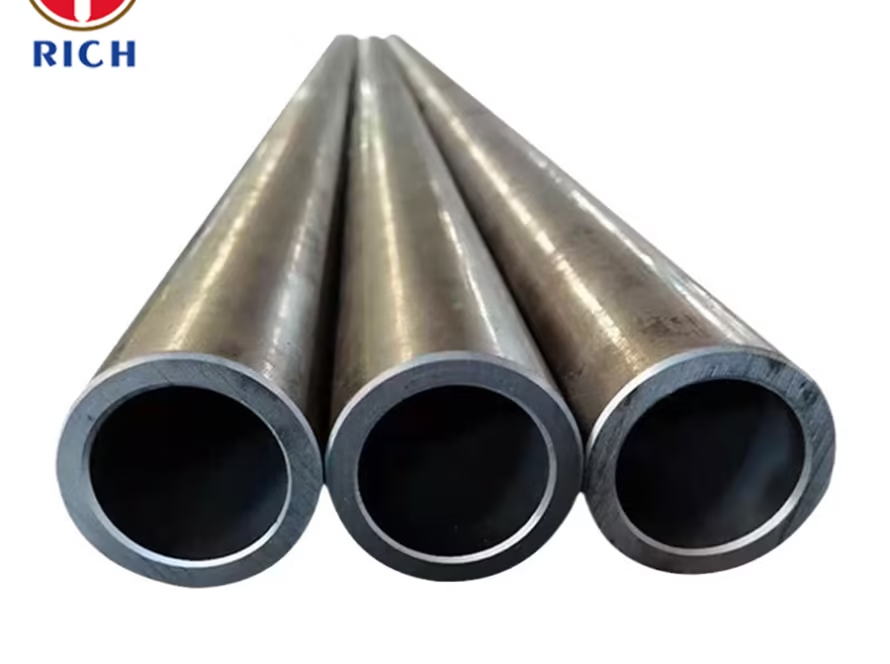

Low alloy steel pipes are widely used in various industries due to their excellent mechanical properties and high resistance to corrosion. One such popular low alloy steel pipe is ASTM A423. In this article, we will explore the material, specification, key features, chemical composition, mechanical properties, steel grade, application, and possible alternative grades of ASTM A423.

Material and Specification

ASTM A423 is a specification that covers seamless and electric-welded low alloy steel tubes for pressure purposes. These tubes are intended for use in applications where corrosion resistance is important. The material used in ASTM A423 pipes is a low alloy steel, which means it contains a small percentage of alloying elements such as chromium, molybdenum, and vanadium.

Key Features

- Corrosion resistance: ASTM A423 pipes exhibit excellent resistance to corrosion, making them suitable for various environments.

- High strength: The low alloy steel used in these pipes provides high strength and durability, making them ideal for applications requiring robustness.

- Seamless and electric-welded: ASTM A423 pipes are available in both seamless and electric-welded forms, providing flexibility in choosing the right type for specific applications.

- Pressure purposes: These pipes are designed to withstand high-pressure conditions, making them suitable for applications where pressure resistance is crucial.

Chemical Composition

| Element | Composition Range (%) |

|---|---|

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 0.60-1.35 |

| Phosphorus (P) | 0.035 max |

| Sulfur (S) | 0.040 max |

| Silicon (Si) | 0.10-0.50 |

| Chromium (Cr) | 0.50-1.25 |

| Molybdenum (Mo) | 0.45-0.65 |

| Vanadium (V) | 0.02-0.10 |

Mechanical Properties

| Property | Minimum Value |

|---|---|

| Tensile Strength | 60,000 psi (415 MPa) |

| Yield Strength | 30,000 psi (205 MPa) |

| Elongation | 30% min |

| Hardness | 79 HRB max |

Steel Grade

ASTM A423 is available in one grade:

- Grade 1: This grade of low alloy steel pipe offers excellent corrosion resistance and is suitable for various applications.

Application

ASTM A423 pipes find extensive use in industries such as oil and gas, petrochemical, power generation, and chemical processing. They are commonly used in applications involving high-pressure environments, such as heat exchangers, boilers, and condensers. The corrosion resistance and high strength of ASTM A423 make it an ideal choice for these demanding applications.

Possible Alternative Grades

While ASTM A423 is a widely used low alloy steel pipe, there are alternative grades available in the market that offer similar properties. Some possible alternative grades include ASTM A335 P11, ASTM A213 T11, and ASTM A199 T11. These grades also provide good corrosion resistance and high strength, making them suitable substitutes for ASTM A423 in certain applications.

In conclusion, ASTM A423 low alloy steel pipes offer excellent corrosion resistance, high strength, and durability. They are widely used in various industries for applications requiring pressure resistance. Understanding the material, specification, key features, chemical composition, mechanical properties, steel grade, application, and possible alternative grades of ASTM A423 can help in selecting the right pipe for specific requirements.