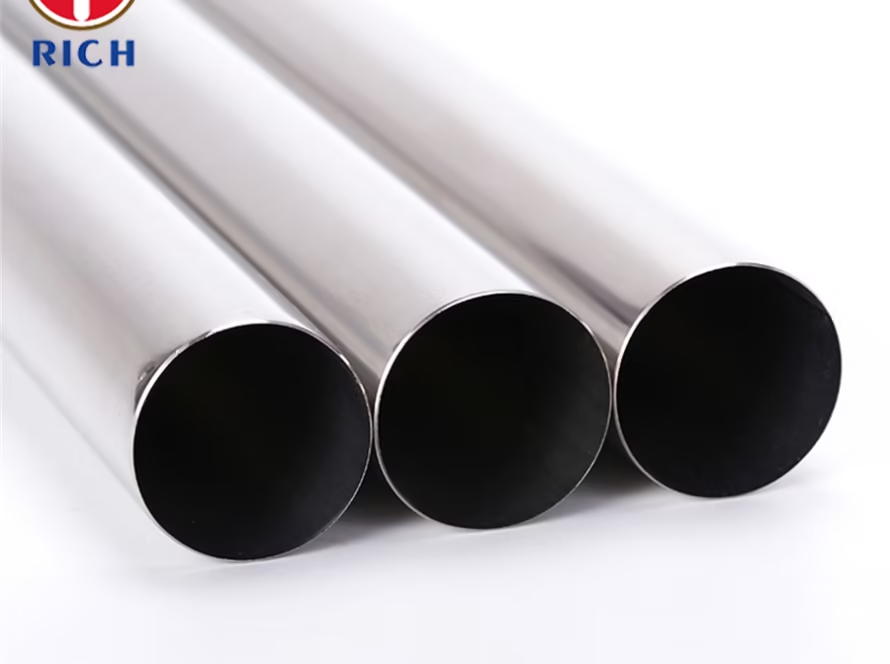

Description

GB/T 14992 Nickel Based Alloy Pipe

Material

Nickel Based Alloy Pipe are renowned for their exceptional resistance to corrosion, high-temperature stability, and excellent mechanical properties. These pipes are primarily composed of nickel, along with other elements such as chromium, molybdenum, and iron, which enhance their performance in challenging environments.

Specification

The GB/T 14992 standard outlines the specifications for nickel-based alloy pipes, ensuring they meet the necessary quality and performance criteria. This includes dimensions, tolerances, and testing methods to guarantee the pipes’ reliability and durability in various applications.

Key Features

- Corrosion Resistance: Exceptional resistance to a wide range of corrosive environments, including acidic and alkaline conditions.

- High-Temperature Stability: Maintains mechanical integrity and strength at elevated temperatures.

- Durability: Long-lasting performance in harsh environments, reducing the need for frequent replacements.

- Versatility: Suitable for various industrial applications, including chemical processing, power generation, and aerospace.

Chemical Composition

| Element | Typical Composition (%) |

|---|---|

| Nickel (Ni) | 50-70 |

| Chromium (Cr) | 15-25 |

| Molybdenum (Mo) | 5-10 |

| Iron (Fe) | 0-20 |

| Others (C, Mn, Si, etc.) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 600-800 MPa |

| Yield Strength | 250-400 MPa |

| Elongation | 30-50% |

| Hardness (Rockwell) | B80-B100 |

Steel Grade

The GB/T 14992 Nickel Based Alloy Pipe standard covers various grades of nickel-based alloy pipes, each tailored for specific applications and environments. Common grades include:

- N06600: Known for its excellent corrosion and oxidation resistance.

- N06625: Offers high strength and resistance to pitting and crevice corrosion.

- N08825: Provides superior resistance to sulfuric and phosphoric acids.

Application

Nickel Based Alloy Pipe are used in a wide range of industries due to their robust properties:

- Chemical Processing: For handling corrosive chemicals and high-temperature processes.

- Oil and Gas: In pipelines and equipment exposed to harsh environments.

- Aerospace: For components that require high strength and resistance to extreme temperatures.

- Power Generation: In turbines and heat exchangers where high-temperature performance is crucial.

Possible Alternative Grades

While GB/T 14992 specifies certain grades, alternative grades may be considered based on specific requirements:

- Inconel 718: Known for its excellent mechanical properties and resistance to creep and stress rupture.

- Hastelloy C276: Offers outstanding resistance to a wide range of severe environments.

- Monel 400: Suitable for applications requiring good mechanical properties and moderate corrosion resistance.