Description

GOST 550-75 12ChM Oil Pressure Tube

Introduction

GOST 550-75 12ChM and 15Ch5M are oil pressure tubes that are widely used in various industries. These tubes are known for their high strength, durability, and excellent performance under extreme conditions. In this article, we will explore the material, specification, key features, chemical composition, mechanical properties, steel grade, application, and possible alternative grades of GOST 550-75 12ChM and 15Ch5M oil pressure tubes.

Material and Specification

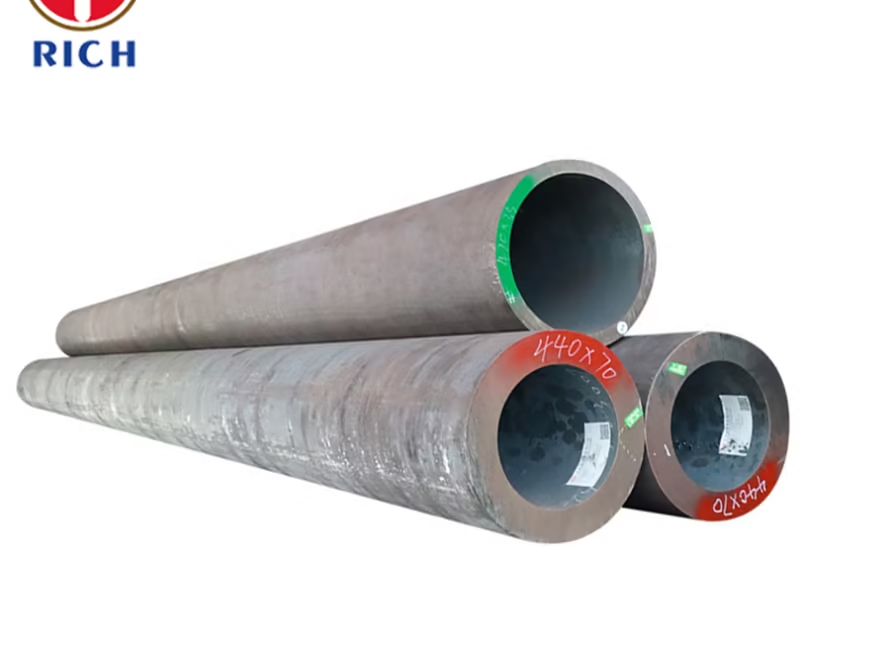

GOST 550-75 12ChM and 15Ch5M oil pressure tubes are made from high-quality alloy steel. The material composition and mechanical properties of these tubes are strictly regulated by the GOST 550-75 standard. The tubes are available in various sizes and thicknesses to meet different application requirements.

Key Features

- High strength: GOST 550-75 12ChM and 15Ch5M oil pressure tubes exhibit excellent strength properties, making them suitable for applications that require high pressure resistance.

- Durability: These tubes are designed to withstand harsh operating conditions, including high temperatures and corrosive environments.

- Good weldability: GOST 550-75 12ChM and 15Ch5M oil pressure tubes can be easily welded, allowing for convenient installation and maintenance.

- Excellent dimensional accuracy: The tubes are manufactured with precise dimensions, ensuring a perfect fit and reliable performance.

Chemical Composition

| Element | 12ChM Composition (%) | 15Ch5M Composition (%) |

|---|---|---|

| Carbon | 0.09-0.16 | 0.12-0.18 |

| Silicon | 0.17-0.37 | 0.17-0.37 |

| Manganese | 0.40-0.70 | 0.40-0.70 |

| Chromium | 0.80-1.10 | 0.80-1.10 |

| Molybdenum | 0.15-0.25 | 0.25-0.35 |

| Nickel | – | 0.30-0.50 |

| Phosphorus | 0.025 max | 0.025 max |

| Sulfur | 0.025 max | 0.025 max |

Mechanical Properties

| Property | 12ChM | 15Ch5M |

|---|---|---|

| Yield Strength (MPa) | 390 min | 490 min |

| Tensile Strength (MPa) | 590-740 | 690-840 |

| Elongation (%) | 14 min | 12 min |

| Impact Toughness (J/cm²) | 98 min | 118 min |

| Hardness (HB) | 197-241 | 217-255 |

Steel Grade

GOST 550-75 12ChM and 15Ch5M oil pressure tubes belong to the group of alloy steels. These tubes are known for their exceptional mechanical properties and high resistance to pressure and temperature.

Application

GOST 550-75 12ChM and 15Ch5M oil pressure tubes find extensive application in various industries, including:

- Oil and gas industry: These tubes are used in oil wells, pipelines, and refineries to transport oil and gas under high pressure.

- Power generation: They are employed in power plants for the construction of boilers, heat exchangers, and other high-pressure systems.

- Chemical industry: GOST 550-75 12ChM and 15Ch5M tubes are utilized in chemical processing plants for handling corrosive fluids and gases.

- Automotive industry: These tubes are used in the manufacturing of engine components, such as cylinders and pistons, due to their high strength and durability.

Possible Alternative Grades

While GOST 550-75 12ChM and 15Ch5M oil pressure tubes are widely used, there are alternative grades available in the market that offer similar properties. Some of the possible alternative grades include ASTM A335 P11, ASTM A213 T11, and DIN 13CrMo44. These grades may vary in terms of chemical composition and mechanical properties, but they can serve as suitable replacements depending on specific application requirements.