Description

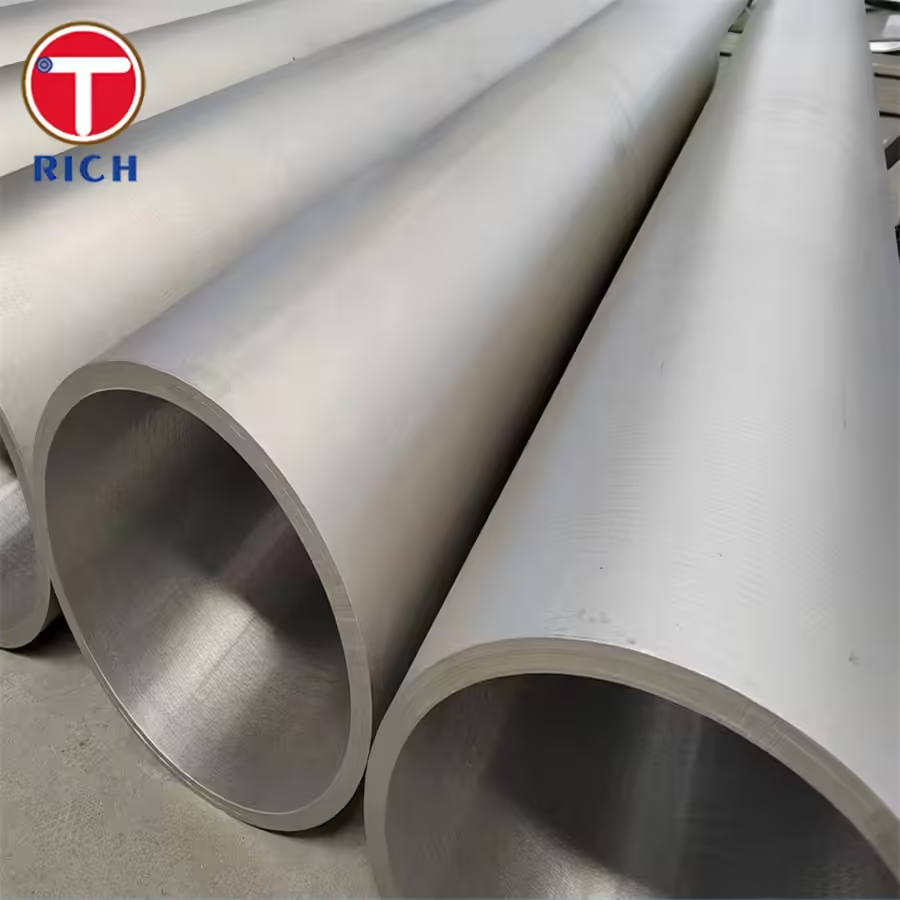

DIN 17456 X2CrNi19-11 X2CrNiMo17-12-2 X5CrNi18-10 X6CrNiTi18-10 X6CrNiNb18-10 Round Stainless Steel Tube

Material and Specification

The DIN 17456 X2CrNi19-11 X2CrNiMo17-12-2 X5CrNi18-10 X6CrNiTi18-10 X6CrNiNb18-10 round stainless steel tube is a high-quality stainless steel product that conforms to the DIN 17456 standard. This standard specifies the technical delivery conditions for seamless stainless steel tubes for general purposes.

The material composition of this stainless steel tube includes various elements that contribute to its exceptional properties. The key features, chemical composition, and mechanical properties of this stainless steel tube are outlined below.

Key Features

- Excellent corrosion resistance: The stainless steel tube is highly resistant to corrosion, making it suitable for various applications in corrosive environments.

- High strength: The tube exhibits good mechanical properties, providing high strength and durability.

- Heat resistance: This stainless steel tube can withstand high temperatures without losing its structural integrity.

- Versatility: The tube’s properties make it suitable for a wide range of applications in industries such as chemical, petrochemical, food processing, and automotive.

Chemical Composition

| Element | X2CrNi19-11 | X2CrNiMo17-12-2 | X5CrNi18-10 | X6CrNiTi18-10 | X6CrNiNb18-10 |

|---|---|---|---|---|---|

| Carbon (C) | 0.03 max | 0.03 max | 0.07 max | 0.08 max | 0.08 max |

| Silicon (Si) | 1.00 max | 1.00 max | 1.00 max | 1.00 max | 1.00 max |

| Manganese (Mn) | 2.00 max | 2.00 max | 2.00 max | 2.00 max | 2.00 max |

| Phosphorus (P) | 0.045 max | 0.045 max | 0.045 max | 0.045 max | 0.045 max |

| Sulfur (S) | 0.015 max | 0.015 max | 0.015 max | 0.015 max | 0.015 max |

| Chromium (Cr) | 18.0-20.0 | 16.0-18.0 | 17.0-19.5 | 17.0-19.0 | 16.0-18.0 |

| Nickel (Ni) | 8.0-12.0 | 10.0-14.0 | 8.0-10.5 | 10.0-12.0 | 10.0-12.0 |

| Molybdenum (Mo) | – | 2.0-3.0 | – | – | – |

| Titanium (Ti) | – | – | – | 5x(C+N) min | – |

| Niobium (Nb) | – | – | – | – | 10xC min |

Mechanical Properties

| Property | X2CrNi19-11 | X2CrNiMo17-12-2 | X5CrNi18-10 | X6CrNiTi18-10 | X6CrNiNb18-10 |

|---|---|---|---|---|---|

| Tensile Strength | 500-700 MPa | 500-700 MPa | 500-700 MPa | 500-700 MPa | 500-700 MPa |

| Yield Strength | 200 MPa min | 200 MPa min | 200 MPa min | 200 MPa min | 200 MPa min |

| Elongation | 40% min | 40% min | 40% min | 40% min | 40% min |

| Hardness (HB) | – | – | – | – | – |

Steel Grade

The steel grade of the DIN 17456 X2CrNi19-11 X2CrNiMo17-12-2 X5CrNi18-10 X6CrNiTi18-10 X6CrNiNb18-10 round stainless steel tube is classified as austenitic stainless steel. Austenitic stainless steels are known for their excellent corrosion resistance, high strength, and good formability.

Application

The DIN 17456 X2CrNi19-11 X2CrNiMo17-12-2 X5CrNi18-10 X6CrNiTi18-10 X6CrNiNb18-10 round stainless steel tube finds application in various industries due to its exceptional properties. Some common applications include:

- Chemical and petrochemical processing: The tube is used in equipment and pipelines for handling corrosive chemicals and fluids.

- Food processing: It is employed in the production of food and beverage processing equipment due to its hygienic properties.

- Automotive industry: The tube is utilized in exhaust systems and other components that require resistance to high temperatures and corrosion.

- Construction: It finds use in architectural structures, such as handrails and balustrades, due to its aesthetic appeal and durability.

Possible Alternative Grades

While the DIN 17456 X2CrNi19-11 X2CrNiMo17-12-2 X5CrNi18-10 X6CrNiTi18-10 X6CrNiNb18-10 stainless steel tube offers excellent properties, there are alternative grades available for specific applications. Some possible alternative grades include:

- X2CrNi18-9

- X2CrNiMo17-13-2

- X5CrNiMo17-12-2

- X6CrNiTi18-10

- X6CrNiNb18-10