Description

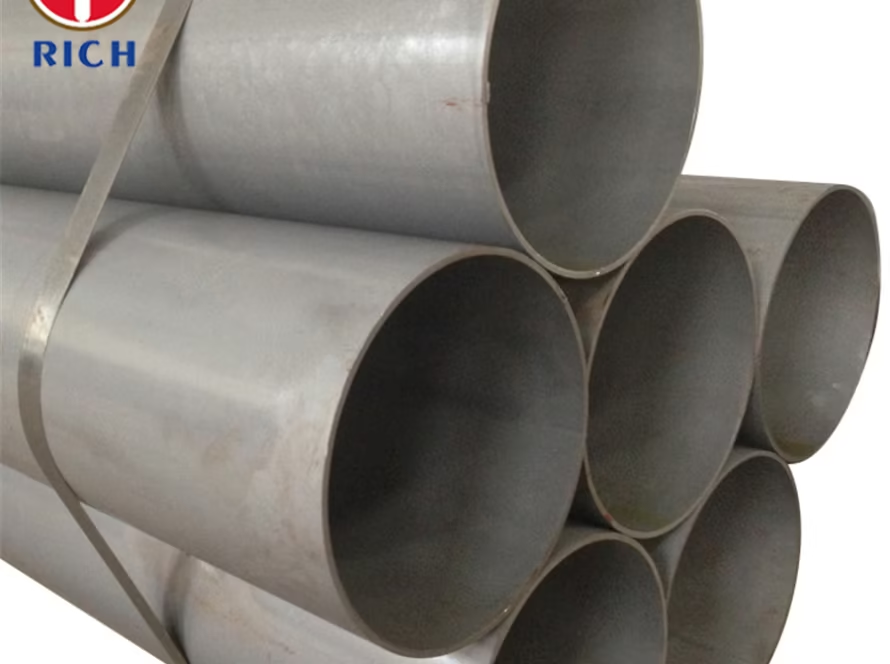

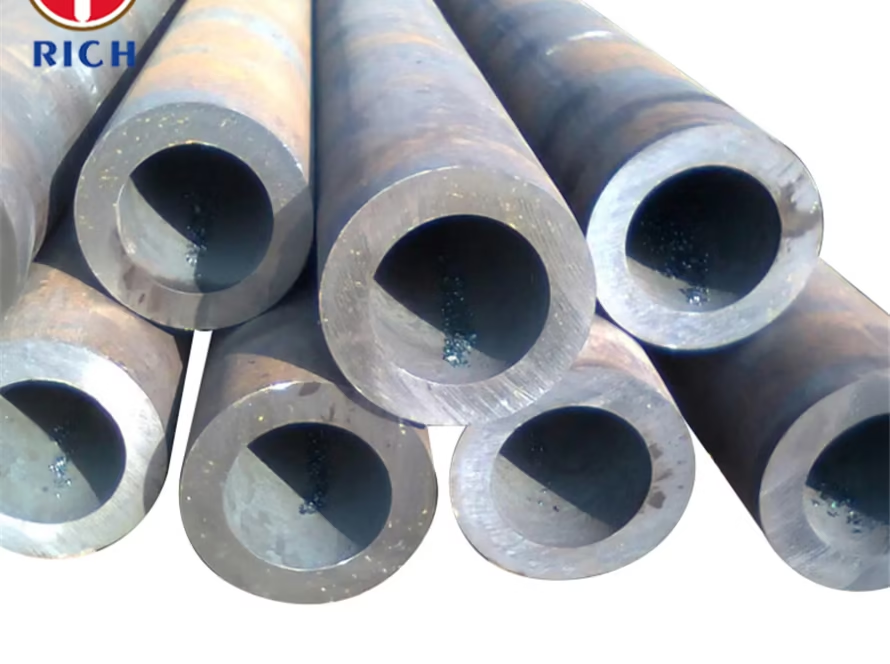

Seamless Precision Steel Tubes DIN 2391

Material and Specification

DIN 2391 is a standard that specifies seamless precision steel tubes. It covers various grades of steel tubes used for precision applications. The specific grades mentioned in this article are St30Al, St30Si, St35, St45, and St52.

Key Features

The seamless precision steel tubes specified by DIN 2391 have several key features that make them suitable for precision applications. These features include:

- High dimensional accuracy: The tubes have precise dimensions, ensuring a tight fit and compatibility with various components.

- Excellent surface finish: The tubes have a smooth surface finish, which is crucial for applications where friction needs to be minimized.

- Tight tolerances: DIN 2391 specifies strict tolerances for the dimensions of the tubes, ensuring consistency and reliability.

- Good machinability: The steel used in these tubes has good machinability, making it easier to process and fabricate.

Chemical Composition

The chemical composition of the specified grades is as follows:

| Steel Grade | Chemical Composition (%) |

|---|---|

| St30Al | C: 0.17-0.24, Si: 0.10-0.35, Mn: 0.40-0.80, P: 0.035 max, S: 0.035 max |

| St30Si | C: 0.17-0.24, Si: 0.10-0.35, Mn: 0.40-0.80, P: 0.035 max, S: 0.035 max |

| St35 | C: 0.17-0.24, Si: 0.10-0.35, Mn: 0.40-0.80, P: 0.035 max, S: 0.035 max |

| St45 | C: 0.42-0.50, Si: 0.10-0.35, Mn: 0.50-0.80, P: 0.035 max, S: 0.035 max |

| St52 | C: 0.22 max, Si: 0.55 max, Mn: 1.60 max, P: 0.025 max, S: 0.025 max |

Mechanical Properties

The mechanical properties of the specified grades are as follows:

| Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| St30Al | 420-550 | 275 min | 21 min |

| St30Si | 420-550 | 275 min | 21 min |

| St35 | 440-570 | 235 min | 25 min |

| St45 | 550-700 | 390 min | 21 min |

| St52 | 580-730 | 420 min | 15 min |

Steel Grade and Application

The specified steel grades have different applications based on their properties. Here are the steel grades and their typical applications:

- St30Al: This grade is commonly used in the automotive industry for manufacturing precision components such as shafts and gears.

- St30Si: It finds application in the production of hydraulic and pneumatic systems, where precision and reliability are crucial.

- St35: This grade is suitable for applications requiring high precision and excellent surface finish, such as in the manufacturing of fuel injection systems.

- St45: It is commonly used in the production of hydraulic cylinders, where high strength and durability are essential.

- St52: This grade is widely used in various industries, including automotive, machinery, and construction, due to its excellent combination of strength and machinability.

Possible Alternative Grades

While DIN 2391 specifies these specific grades, there are alternative grades available in other standards that offer similar properties. Some possible alternative grades include ASTM A519, EN 10305-1, and JIS G3445, which provide seamless precision steel tubes suitable for various applications.