Description

JIS G3466 STKR400 STKR490 Structural Steel Pipe

Introduction

JIS G3466 is a Japanese industrial standard that specifies the requirements for square, rectangular, and circular structural steel pipe used in construction projects. This standard covers two grades of structural steel pipes: STKR400 and STKR490. In this article, we will explore the material, specification, key features, chemical composition, mechanical properties, steel grade, application, and possible alternative grades of JIS G3466 STKR400 and STKR490 structural steel pipes.

Material and Specification

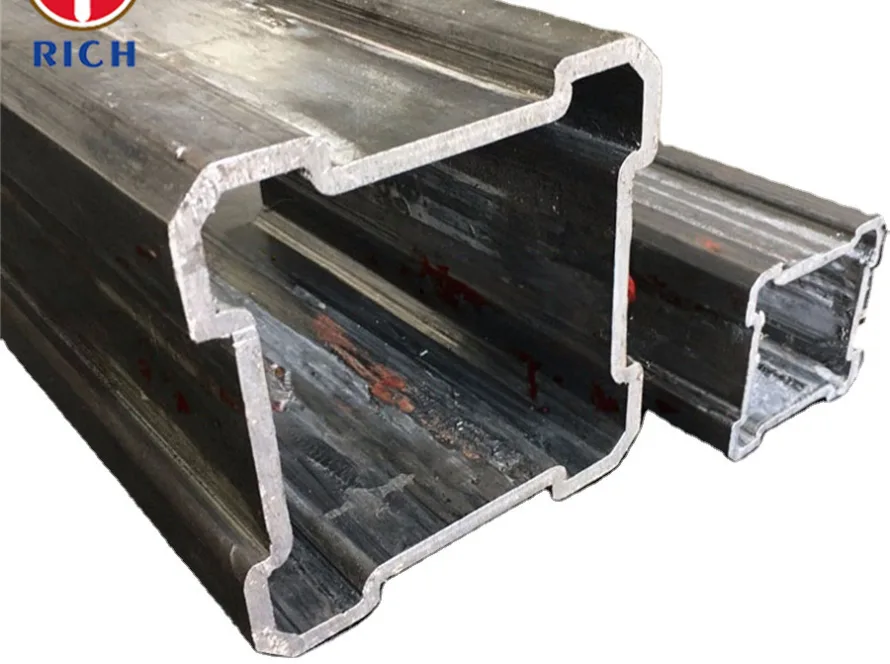

JIS G3466 STKR400 and STKR490 structural steel pipes are made from carbon steel and are available in square, rectangular, and circular shapes. These pipes are manufactured by cold forming and electric resistance welding methods. The standard specifies the dimensions, tolerances, and technical requirements for these pipes.

Key Features

The key features of JIS G3466 STKR400 and STKR490 structural steel pipes include:

- High strength: These pipes are designed to withstand high loads and provide structural stability.

- Excellent weldability: The electric resistance welding method used in their manufacturing ensures strong and reliable weld joints.

- Durable: The carbon steel material used in these pipes offers excellent durability and longevity.

- Versatile: The square, rectangular, and circular shapes of these pipes make them suitable for various construction applications.

Chemical Composition

| Element | STKR400 Composition (%) | STKR490 Composition (%) |

|---|---|---|

| Carbon (C) | 0.25 max | 0.18 max |

| Silicon (Si) | – | – |

| Manganese (Mn) | – | – |

| Phosphorus (P) | 0.040 max | 0.040 max |

| Sulfur (S) | 0.040 max | 0.040 max |

Mechanical Properties

| Property | STKR400 | STKR490 |

|---|---|---|

| Tensile Strength (MPa) | 400 min | 490 min |

| Yield Strength (MPa) | 245 min | 325 min |

| Elongation (%) | 23 min | 23 min |

| Bending Test (Diameter: 3D) | No cracks or flaws | No cracks or flaws |

Steel Grade

JIS G3466 STKR400 and STKR490 are the steel grades specified in this standard. STKR400 has a minimum tensile strength of 400 MPa and a minimum yield strength of 245 MPa. STKR490 has a higher tensile strength of 490 MPa and a minimum yield strength of 325 MPa.

Application

JIS G3466 STKR400 and STKR490 structural steel pipes are widely used in various construction applications, including:

- Building frames: These pipes are used for the construction of building frames, providing structural support and stability.

- Bridges: STKR400 and STKR490 pipes are suitable for bridge construction due to their high strength and durability.

- Infrastructure projects: These pipes are used in infrastructure projects such as highways, railways, and airports for their load-bearing capabilities.

- Machinery and equipment: STKR400 and STKR490 pipes find applications in the manufacturing of machinery and equipment where structural strength is crucial.

Possible Alternative Grades

While JIS G3466 STKR400 and STKR490 are widely used, there are alternative grades available in other international standards. Some possible alternative grades include:

- ASTM A500: This American standard specifies cold-formed welded and seamless carbon steel structural tubing in round, square, and rectangular shapes.

- EN 10219: This European standard covers cold-formed welded structural hollow sections of non-alloy and fine grain steels.

It is important to consult the specific requirements and regulations of the project to determine the most suitable alternative grade for a particular application.