What is Cylindricity?

Cylindricity is a geometric tolerance in the field of engineering and manufacturing, particularly in precision machining and quality control. It specifies how closely the shape of an object’s surface conforms to a perfect cylinder. This concept is essential for ensuring the proper fit and function of cylindrical parts, particularly in assemblies where performance and reliability are critical.

Understanding Cylindricity

Cylindricity involves two main components:

- Profile of a Surface: The profile of a surface in this context refers to the ideal cylindrical shape that a real cylindrical surface should match.

- Deviation From the Ideal Form: The tolerance defines the allowable deviation from the true cylindrical form.

Cylindricity is concerned with the entire surface of the cylinder, not just individual features. It ensures that the cylindrical surface is uniform and aligns perfectly with a reference cylinder defined by two coaxial cylinders—a minimum and a maximum—inside which the real surface must lie.

Importance in Industry

- Precision and Reliability: Cylindricity is crucial in industries where parts must fit together perfectly, such as in aerospace, automotive, and mechanical engineering.

- Performance: Ensuring correct cylindricity can improve the performance of mechanical systems such as bearings, seals, and pistons.

- Reduced Wear: Proper cylindricity reduces wear and tear in components by ensuring even contact and distribution of forces.

Measurement Techniques

Several methods exist for measuring cylindricity, including:

- Coordinate Measuring Machines (CMMs): These machines provide high-precision measurements by probing the surface of an object and computing the deviation from the ideal geometry.

- Roundness Testers: These devices specialize in evaluating both roundness and cylindricity by rotating the part to gather data about the surface profile.

- Laser Scanners: Used for non-contact measurements, laser scanners provide a detailed 3D map of the surface to assess conformity with the ideal cylinder.

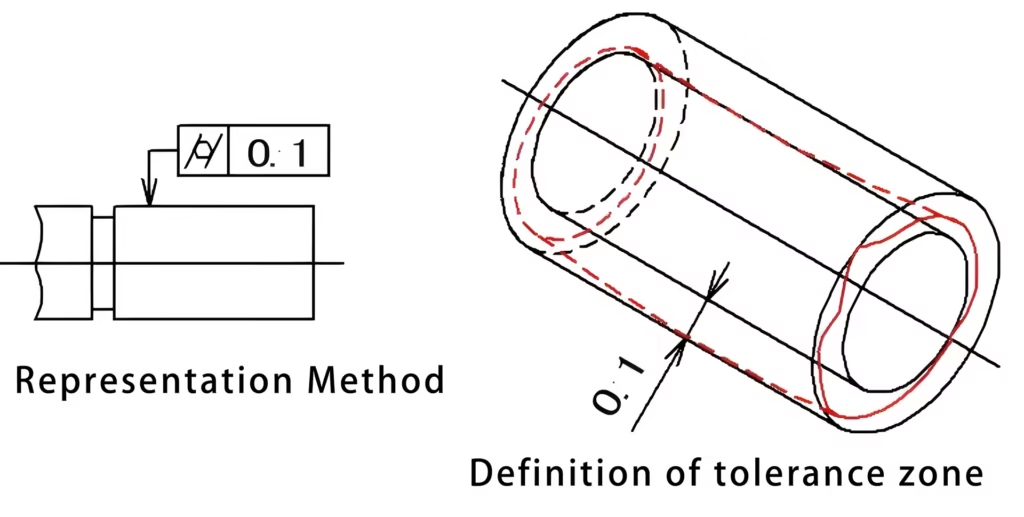

Representation in Engineering Drawings

In technical drawings, cylindricity is commonly indicated using symbols from the Geometric Dimensioning and Tolerancing (GD&T) system. The GD&T cylindricity symbol is a circle with two parallel lines on either side, representing the allowable tolerance zone.

Conclusion

Cylindricity is a vital specification in ensuring the quality and functionality of cylindrical components. By maintaining proper cylindricity, manufacturers can ensure that parts will fit together as intended, perform efficiently, and have longer lifespans. Understanding and applying the principles of cylindricity can lead to significant improvements in product quality and manufacturing efficiency.