What is Honed Tubing?

When industries talk about honed hydraulic cylinder tubing, smooth surface finishes, and reliable performance under pressure, honed tubing is often the centerpiece of the conversation. But what exactly is honed tubing, and why is it different from other types of steel pipes? Let’s explore this in detail.

1. What is Honed Tubing?

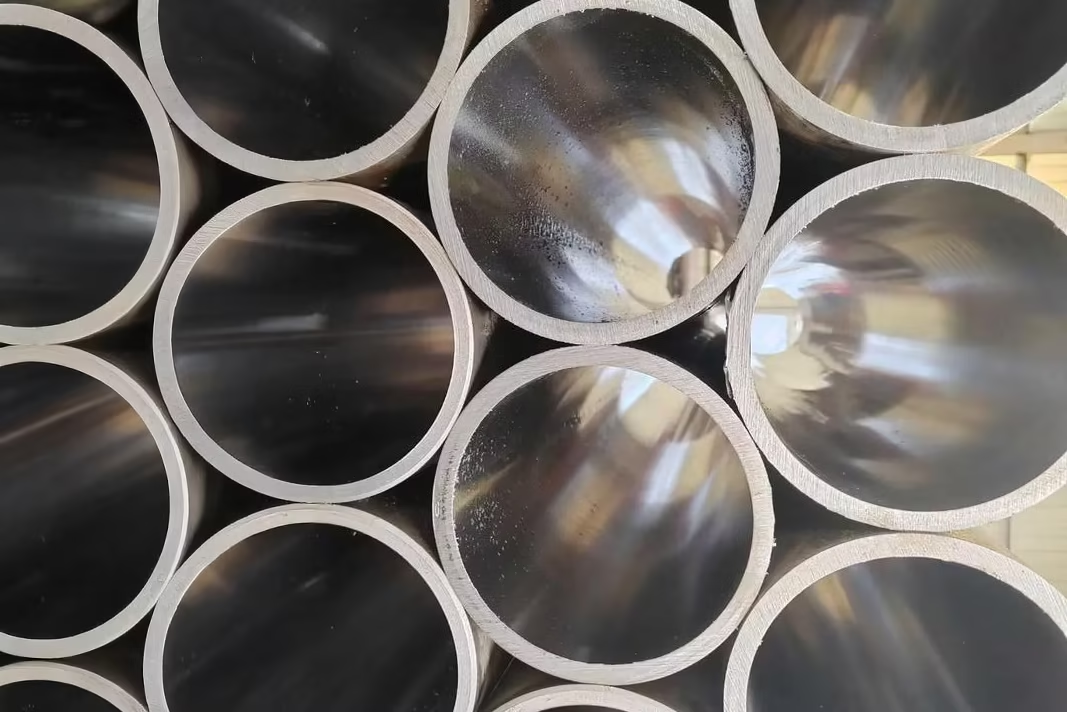

Honed tubing is a precision steel pipe that has undergone an internal honing process. The goal of honing is to achieve:

-

High dimensional accuracy: Ensuring the inside diameter (ID) remains uniform throughout the length.

-

Smooth internal finish: Achieving a low roughness value (commonly Ra 0.2–0.4 μm), critical for sealing performance.

-

Improved roundness and straightness: Essential for applications like hydraulic and pneumatic cylinders.

Because of these features, honed tubes are widely used in hydraulic cylinders, pneumatic cylinders, and other mechanical systems where fluid tightness and wear resistance are crucial.

2. Production Process of Honed Tubing

The production of honed tubing is not just about shaping steel—it’s about precision finishing. The typical process includes:

-

Raw material preparation – Seamless or DOM (Drawn Over Mandrel) tubes are chosen as the base.

-

Cold drawing – Reduces diameter, improves dimensional accuracy, and increases strength.

-

Heat treatment – Relieves stress and improves machinability.

-

Honing – A specialized abrasive process removes small amounts of material from the ID to achieve the required smoothness and precision.

-

Cleaning and inspection – Tubes are thoroughly cleaned and tested for dimensional accuracy, straightness, and surface roughness.

The honing step is the defining stage, giving honed tubing its unique quality compared to standard steel pipes.

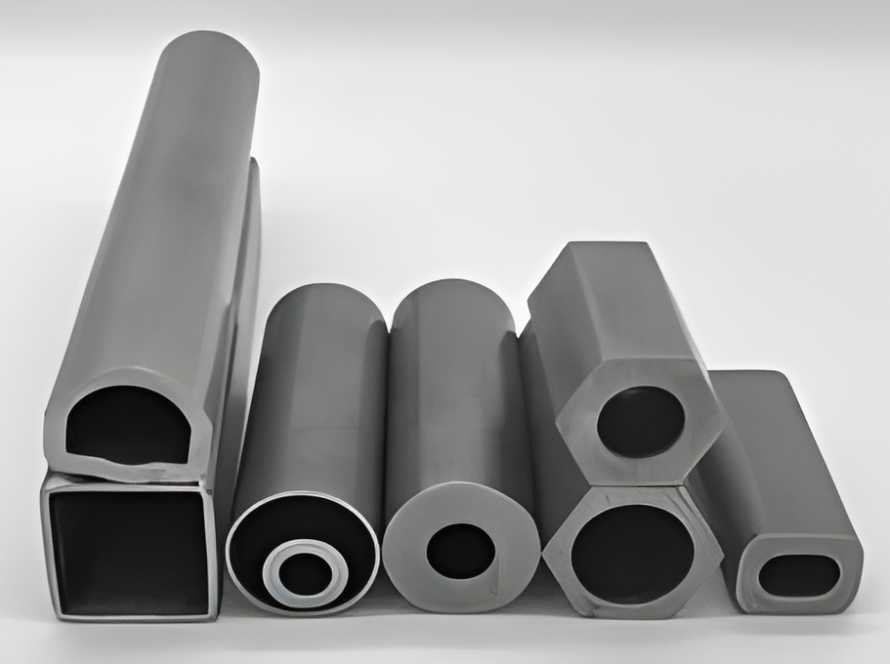

3. Differences Between Honed Tubing and Other Steel Pipes

-

Surface Finish

-

Ordinary pipes: Rough ID surface, not suitable for sealing.

-

Honed tubing: Mirror-like finish, ensuring perfect sealing with piston seals.

-

-

Dimensional Tolerance

-

Ordinary pipes: Broad tolerances, suitable for general transport.

-

Honed tubing: Tight tolerances (±0.02 mm or better), crucial for hydraulic applications.

-

-

Application Scope

-

Ordinary pipes: Conveying fluids, structural use.

-

Honed tubing: Precision cylinders, mechanical parts requiring high wear resistance.

-

-

Cost

-

Honed tubes are more expensive due to the additional processing steps but save costs in long-term reliability.

-

4. Alternatives to Honed Tubing: Rolled Tubing

While honing is one way to finish the inside surface, another alternative is rolled tubing, also known as skived and roller burnished tubing (SRB tubing).

-

Production: Instead of honing, SRB uses a skiving tool to remove material and a roller burnishing tool to cold-work the surface.

-

Advantages: Higher production speed, excellent surface finish, improved fatigue strength due to cold work.

-

Comparison with Honed Tubing:

-

Honed tubing: More precise in small batches, highly flexible for custom sizes.

-

Rolled tubing: More efficient for large-scale production with excellent repeatability.

-

3 Comments

helloboy1979

Спасибо, это именно то, что мне было нужно.

user.94374.2951

Sooooooooooooooo good

x666

This is a complete and perfect introduction to grinding tubes; I need them.