Description

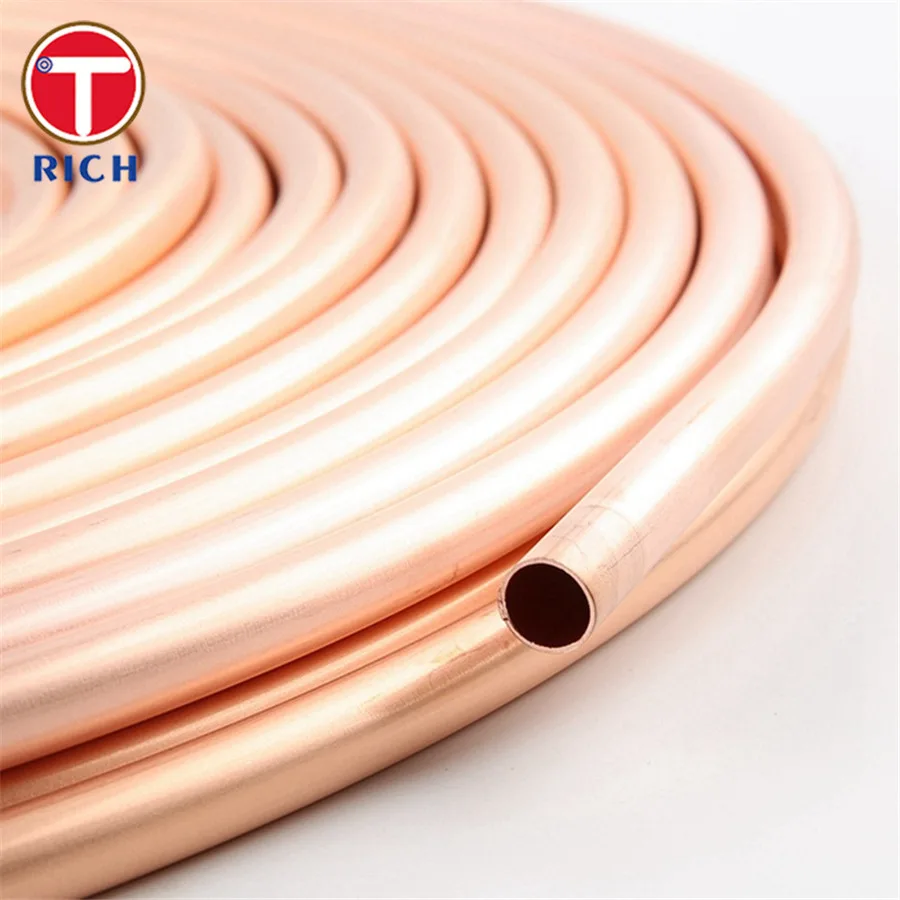

Copper Pipe ASTM B111

Introduction

Copper pipes are widely used in various industries due to their excellent corrosion resistance, high thermal conductivity, and durability. One of the commonly used copper pipe standards is ASTM B111. In this article, we will explore the material, specification, key features, chemical composition, mechanical properties, steel grade, application, and possible alternative grades of Copper Pipe ASTM B111.

Material and Specification

Copper Pipe ASTM B111 is a seamless tube made from high-quality copper alloy. It is specifically designed to meet the requirements set by the ASTM International, a globally recognized standards organization. The ASTM B111 standard provides guidelines for the manufacturing and testing of copper pipes.

Key Features

Copper Pipe ASTM B111 offers several key features that make it a preferred choice in various applications:

- Corrosion Resistance: Copper pipes exhibit excellent resistance to corrosion, making them suitable for use in both indoor and outdoor environments.

- Thermal Conductivity: Copper is known for its high thermal conductivity, allowing efficient heat transfer in applications such as HVAC systems and heat exchangers.

- Durability: Copper pipes are highly durable and can withstand high pressures and temperatures, making them suitable for demanding applications.

- Versatility: Copper pipes can be easily bent, shaped, and joined, providing flexibility in installation and design.

Chemical Composition

The chemical composition of Copper Pipe ASTM B111 typically includes the following elements:

| Element | Composition Range (%) |

|---|---|

| Copper (Cu) | 99.9 min |

| Phosphorus (P) | 0.015 – 0.040 |

| Arsenic (As) | 0.02 – 0.06 |

| Zinc (Zn) | 0.02 – 0.06 |

| Lead (Pb) | 0.02 – 0.06 |

| Iron (Fe) | 0.10 max |

| Aluminum (Al) | 0.005 max |

| Tin (Sn) | 0.005 max |

| Nickel (Ni) | 0.005 max |

| Antimony (Sb) | 0.005 max |

| Silicon (Si) | 0.10 max |

| Sulfur (S) | 0.006 max |

Mechanical Properties

The mechanical properties of Copper Pipe ASTM B111 are as follows:

| Property | Value |

|---|---|

| Tensile Strength | 275 MPa min |

| Yield Strength | 105 MPa min |

| Elongation | 35% min |

| Hardness (Rockwell B) | 60 max |

Steel Grade

Copper Pipe ASTM B111 does not have a specific steel grade, as it is primarily composed of copper and various alloying elements.

Application

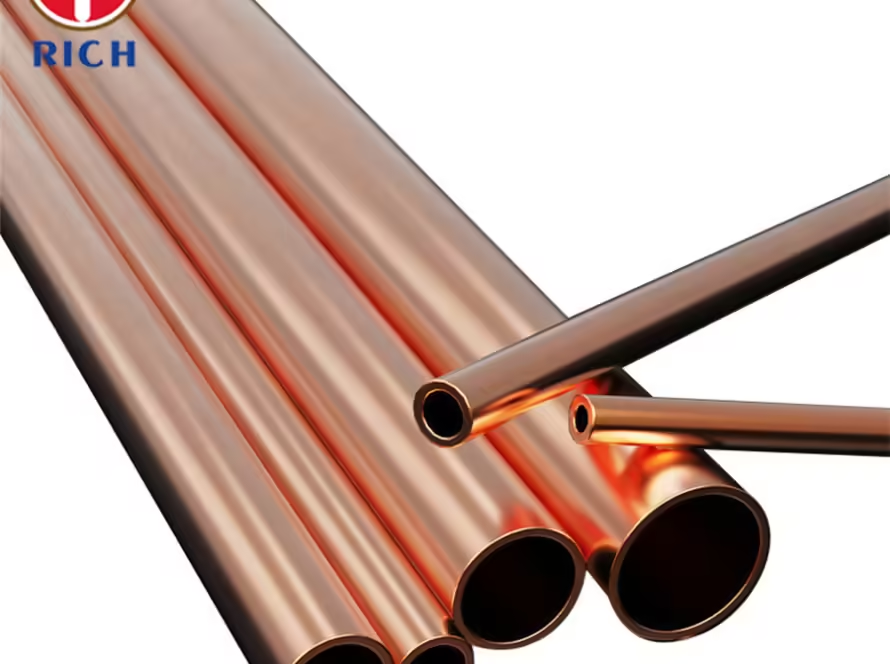

Copper Pipe ASTM B111 finds extensive application in various industries, including:

- HVAC Systems: Copper pipes are commonly used for refrigerant lines, condenser coils, and heat exchangers in heating, ventilation, and air conditioning systems.

- Plumbing: Copper pipes are widely used for water supply lines, both in residential and commercial buildings.

- Marine Industry: Due to its excellent corrosion resistance, copper pipes are utilized in shipbuilding and offshore applications.

- Power Generation: Copper pipes are employed in power plants for cooling systems and heat transfer applications.

- Industrial Processes: Copper pipes are used in various industrial processes, including chemical processing, oil and gas, and manufacturing.

Possible Alternative Grades

While Copper Pipe ASTM B111 is a widely accepted standard, there are alternative grades available in the market that offer similar properties. Some possible alternative grades include:

- Copper Pipe ASTM B280

- Copper Pipe ASTM B88

- Copper Pipe ASTM B306

It is essential to consult with industry experts and consider specific application requirements when selecting an alternative grade.

Conclusion

Copper Pipe ASTM B111 is a high-quality seamless tube that offers excellent corrosion resistance, thermal conductivity, and durability. Its chemical composition and mechanical properties meet the standards set by ASTM International. With its versatility and wide range of applications, Copper Pipe ASTM B111 continues to be a popular choice in various industries. However, alternative grades such as ASTM B280, ASTM B88, and ASTM B306 can also be considered based on specific requirements.