Description

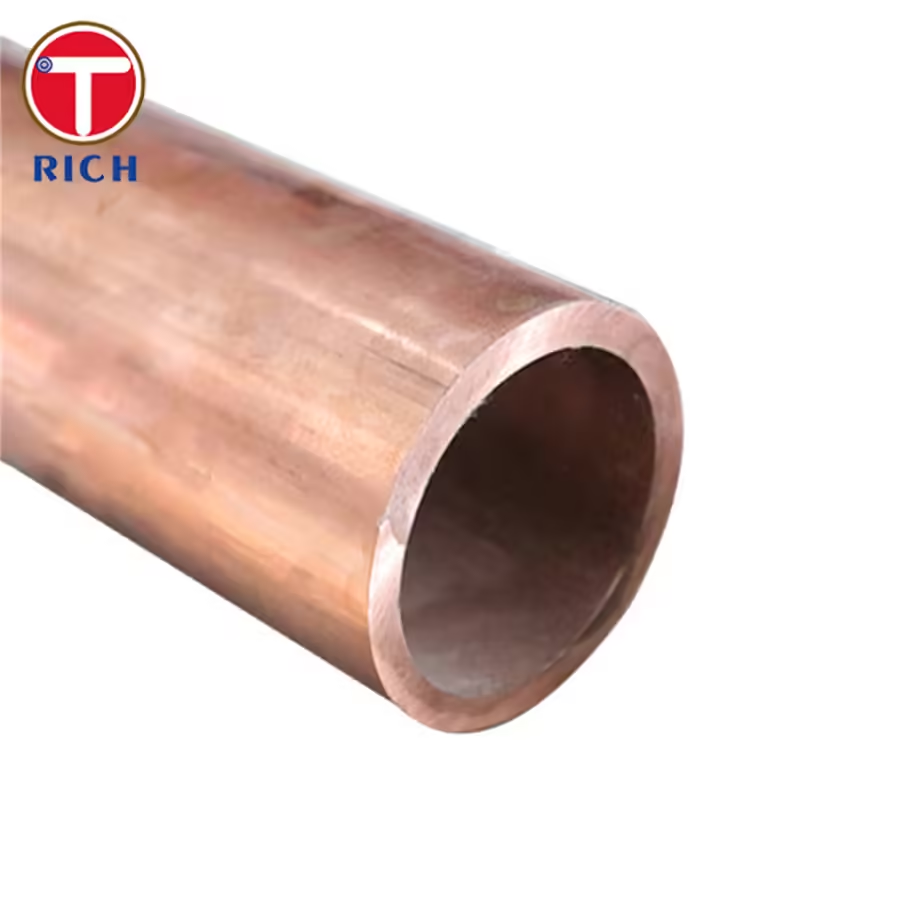

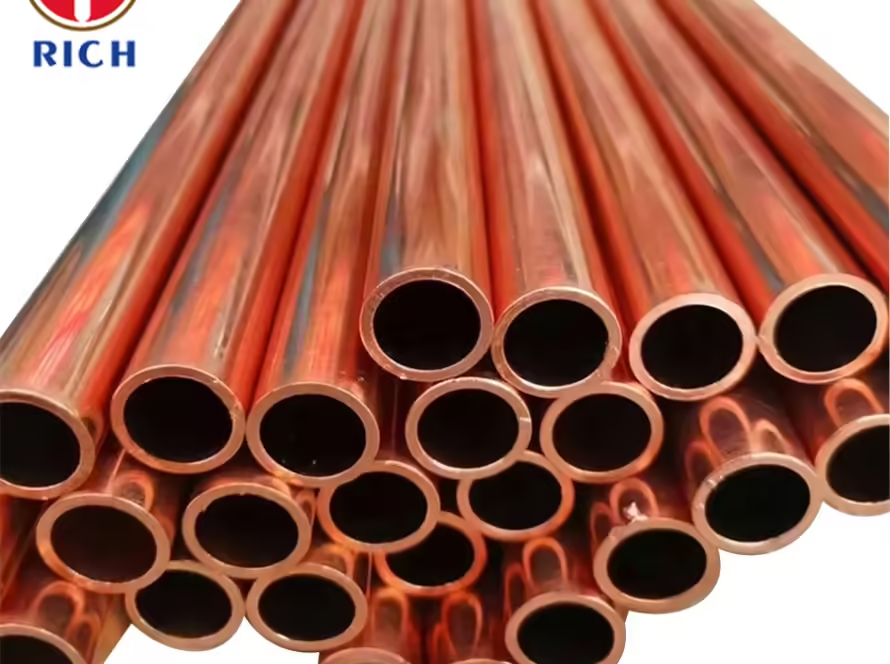

GB/T 17791 TU1 TU2 TP1 TP2 T2 Copper Alloy Tube

Material

The GB/T 17791 standard specifies the requirements for copper alloy tube used in various applications. These tubes are known for their excellent corrosion resistance, high thermal and electrical conductivity, and good mechanical properties. The standard covers different grades of copper alloys, each with unique characteristics suitable for specific applications.

Specification

The specification outlines the dimensions, tolerances, and surface quality of the copper alloy tubes. The tubes are available in various sizes and shapes, including round, square, and rectangular profiles, to meet diverse industrial needs.

Key Features

- Corrosion Resistance: Copper alloys exhibit excellent resistance to corrosion, making them suitable for harsh environments.

- High Conductivity: These materials are known for their superior electrical and thermal conductivity.

- Good Machinability: Copper alloys can be easily machined, allowing for precise fabrication.

- Versatility: Suitable for a wide range of applications, from plumbing to electrical components.

Chemical Composition

| Grade | Copper (Cu) | Tin (Sn) | Lead (Pb) | Zinc (Zn) | Nickel (Ni) | Other Elements |

|---|---|---|---|---|---|---|

| TU1 | ≥ 99.90% | – | – | – | – | – |

| TU2 | ≥ 99.70% | – | – | – | – | – |

| TP1 | ≥ 99.90% | – | – | – | – | – |

| TP2 | ≥ 99.70% | – | – | – | – | – |

| T2 | ≥ 99.90% | – | – | – | – | – |

Mechanical Properties

| Property | TU1 | TU2 | TP1 | TP2 | T2 |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | ≥ 210 | ≥ 200 | ≥ 210 | ≥ 200 | ≥ 210 |

| Yield Strength (MPa) | ≥ 70 | ≥ 65 | ≥ 70 | ≥ 65 | ≥ 70 |

| Elongation (%) | ≥ 30 | ≥ 30 | ≥ 30 | ≥ 30 | ≥ 30 |

| Hardness (HB) | ≤ 100 | ≤ 100 | ≤ 100 | ≤ 100 | ≤ 100 |

Steel Grade

The copper alloy tubes specified in GB/T 17791 are categorized into different grades based on their chemical composition and mechanical properties. The most common grades include TU1, TU2, TP1, TP2, and T2.

Application

Copper alloy tubes are widely used in various industries, including:

- Electrical Engineering: For wiring and electrical components due to high conductivity.

- Plumbing: In plumbing systems for their corrosion resistance.

- Heat Exchangers: In HVAC systems for efficient heat transfer.

- Automotive: In various automotive components for durability and performance.

Possible Alternative Grades

While the GB/T 17791 grades are widely used, there are alternative grades that may be suitable depending on the application requirements. These include:

- C11000: A high-purity copper alloy with excellent conductivity.

- C26000: A brass alloy known for its good mechanical properties and corrosion resistance.

- C70600: A copper-nickel alloy that offers enhanced corrosion resistance in marine environments.