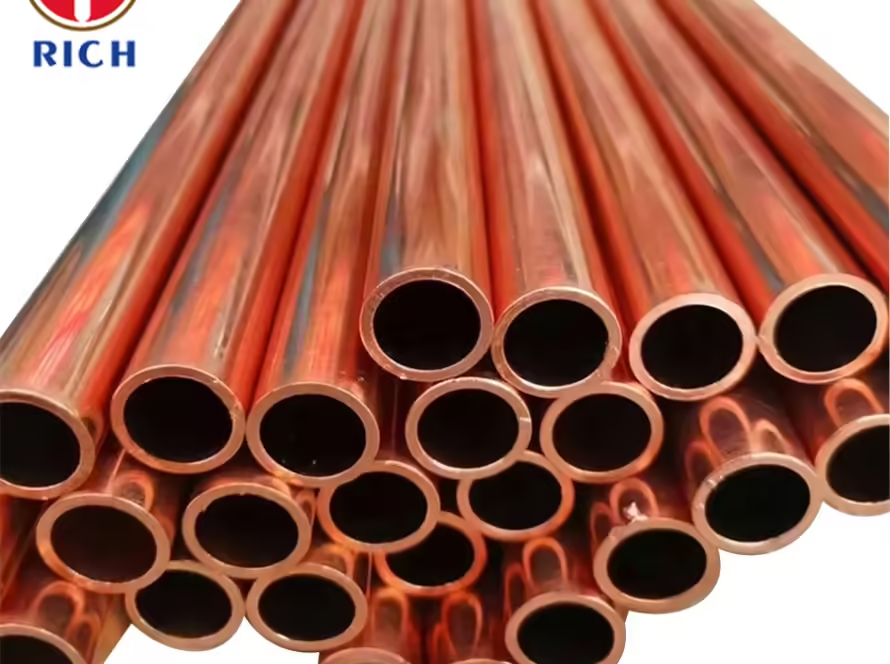

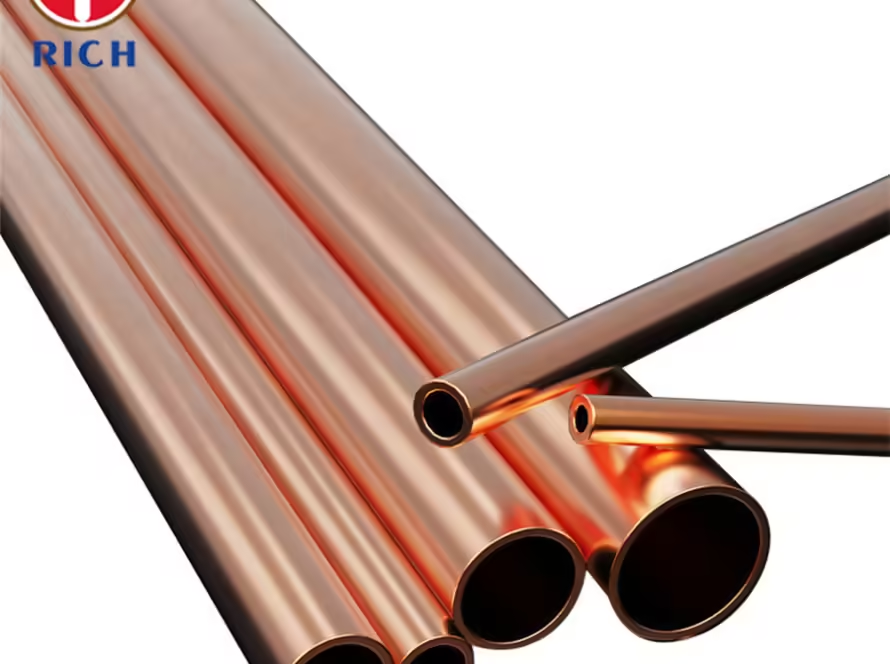

Description

EN-12735 CW024A CW107C Copper Alloy Pipe

Material

EN-12735 is a European standard that specifies the requirements for copper and copper alloy pipes. The CW024A and CW107C are specific grades of copper alloys that are commonly used in various applications due to their excellent properties.

Specification

The EN-12735 standard outlines the specifications for copper alloy pipe, including dimensions, tolerances, and mechanical properties. These pipes are typically used in refrigeration, air conditioning, and plumbing systems.

Key Features

- Corrosion Resistance: Excellent resistance to corrosion, making it suitable for various environments.

- Thermal Conductivity: High thermal conductivity, ideal for heat exchange applications.

- Ductility: Good ductility allows for easy fabrication and installation.

- Weldability: Can be easily welded, facilitating construction and repair processes.

Chemical Composition

| Element | CW024A (%) | CW107C (%) |

|---|---|---|

| Copper (Cu) | 99.90 | 99.90 |

| Silver (Ag) | 0.01 | 0.01 |

| Oxygen (O) | 0.05 | 0.05 |

| Phosphorus (P) | 0.01 | 0.01 |

| Lead (Pb) | 0.005 | 0.005 |

| Other Elements | Trace | Trace |

Mechanical Properties

| Property | CW024A | CW107C |

|---|---|---|

| Yield Strength (MPa) | 210 | 220 |

| Ultimate Tensile Strength (MPa) | 350 | 360 |

| Elongation (%) | 30 | 25 |

| Hardness (HB) | 70 | 75 |

Steel Grade

While CW024A and CW107C are primarily copper alloys, they can be compared to certain steel grades in terms of mechanical properties. However, they are not classified as steel grades.

Application

The CW024A and CW107C copper alloy pipe are widely used in:

- Refrigeration Systems: For transporting refrigerants.

- Air Conditioning: In HVAC systems for efficient heat transfer.

- Plumbing: For water supply and drainage systems.

- Electrical Applications: Due to their excellent conductivity.

Possible Alternative Grades

- CW024A Alternatives: CW025A, CW026A

- CW107C Alternatives: CW108C, CW109C