Description

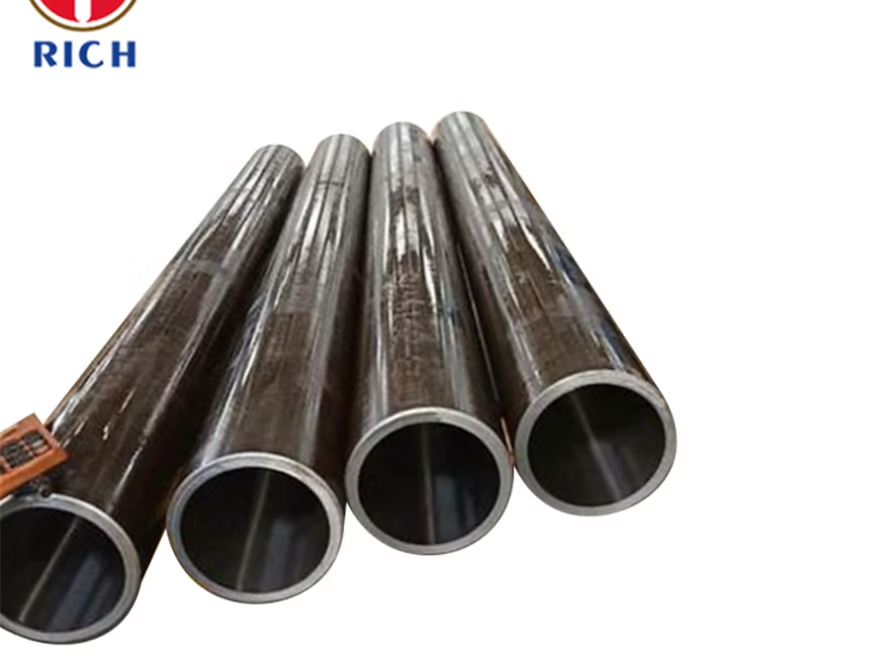

Heat Resistant Tubing DIN 17175

Introduction

DIN 17175 is a standard specification for seamless carbon steel boiler tubes used in high-temperature service. This article focuses on the heat resistant tubing grades St35.8, St45.8, 17Mn4, and 19Mn5, which are commonly used in various industrial applications. We will explore the material, specification, key features, chemical composition, mechanical properties, steel grade, applications, and possible alternative grades for these heat resistant tubes.

Material and Specification

The DIN 17175 standard covers seamless tubes made from carbon steel. The heat resistant tubing grades St35.8, St45.8, 17Mn4, and 19Mn5 are specified under this standard. These tubes are designed to withstand high temperatures and are widely used in the manufacturing of boilers, heat exchangers, and pressure vessels.

Key Features

The key features of DIN 17175 heat resistant tubing include:

-

High Temperature Resistance: These tubes are specifically designed to withstand high temperatures, making them suitable for applications involving heat transfer and thermal energy.

-

Seamless Construction: The seamless manufacturing process ensures the absence of welds, providing enhanced strength and reliability.

-

Excellent Mechanical Properties: The heat resistant tubing exhibits excellent mechanical properties, including high tensile strength, good elongation, and superior impact resistance.

-

Corrosion Resistance: The carbon steel composition of these tubes offers good resistance against corrosion, making them suitable for various industrial environments.

Chemical Composition

The following table presents the chemical composition of DIN 17175 heat resistant tubing grades:

| Steel Grade | Chemical Composition (%) |

|---|---|

| St35.8 | C: 0.17-0.23, Si: 0.10-0.35, Mn: 0.40-0.80, P: 0.040 max, S: 0.040 max |

| St45.8 | C: 0.21-0.27, Si: 0.10-0.35, Mn: 0.40-1.20, P: 0.040 max, S: 0.040 max |

| 17Mn4 | C: 0.14-0.20, Si: 0.20-0.40, Mn: 0.90-1.20, P: 0.040 max, S: 0.040 max |

| 19Mn5 | C: 0.17-0.23, Si: 0.10-0.35, Mn: 1.15-1.50, P: 0.040 max, S: 0.040 max |

Mechanical Properties

The mechanical properties of DIN 17175 heat resistant tubing grades are as follows:

| Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Energy (J) |

|---|---|---|---|---|

| St35.8 | 360-480 | 235 min | 25 min | – |

| St45.8 | 410-530 | 255 min | 21 min | – |

| 17Mn4 | 460-580 | 270 min | 20 min | – |

| 19Mn5 | 510-610 | 320 min | 17 min | – |

Steel Grade and Application

The steel grades covered by DIN 17175, including St35.8, St45.8, 17Mn4, and 19Mn5, find applications in various industries. These heat resistant tubes are commonly used in:

-

Boiler Tubes: They are extensively used in the manufacturing of boilers for power generation, heating systems, and industrial processes.

-

Heat Exchangers: The tubes are employed in heat exchangers to transfer thermal energy between fluids at different temperatures.

-

Pressure Vessels: DIN 17175 heat resistant tubing is suitable for pressure vessel applications where high-temperature resistance is required.

Possible Alternative Grades

While DIN 17175 heat resistant tubing grades are widely used, there are alternative grades available that offer similar properties. Some of the possible alternative grades include:

-

ASTM A192: This specification covers seamless carbon steel boiler tubes similar to DIN 17175 St35.8.

-

ASTM A210: It covers seamless medium-carbon steel boiler and superheater tubes, which can be used as alternatives to St45.8.

-

ASTM A178: This specification covers electric-resistance-welded carbon steel and carbon-manganese steel boiler tubes, which can be considered as alternatives to 17Mn4 and 19Mn5.

In conclusion, DIN 17175 St35.8, St45.8, 17Mn4, and 19Mn5 heat resistant tubing are widely used in high-temperature applications such as boilers, heat exchangers, and pressure vessels. These tubes offer excellent mechanical properties, corrosion resistance, and high-temperature resistance. Additionally, there are alternative grades available that can be considered based on specific requirements.