Description

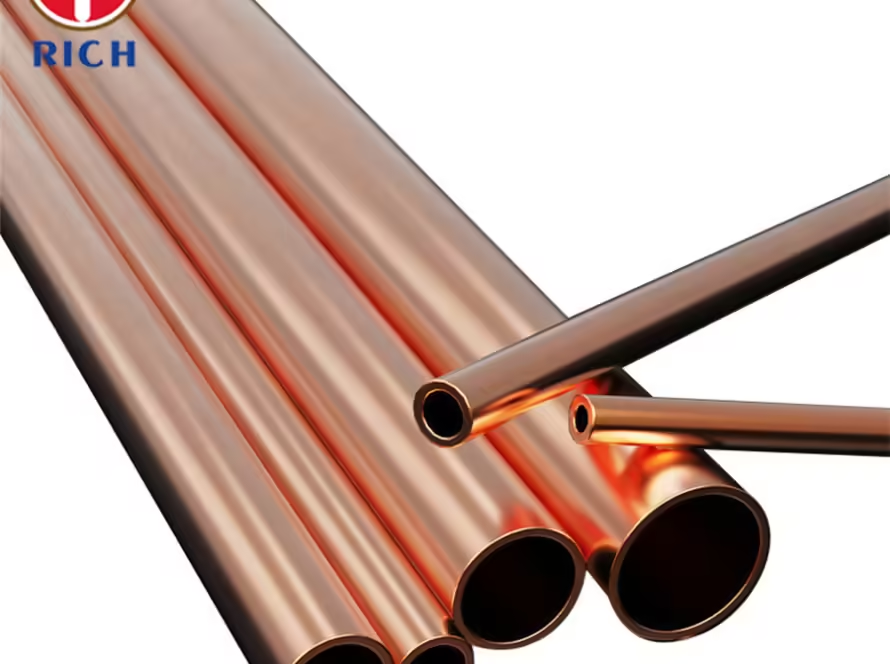

ASTM B88 C10200 C12000 C12200 Seamless Copper Water Tube

Material

ASTM B88 is a standard specification for seamless copper water tube used in plumbing, heating, and other applications. The tubes are made from high-quality copper alloys, specifically C10200, C12000, and C12200, which are known for their excellent corrosion resistance and thermal conductivity.

Specification

The specification outlines the requirements for seamless copper water tubes, including dimensions, tolerances, and mechanical properties. The tubes are typically used in applications where high strength and resistance to corrosion are essential.

Key Features

- Corrosion Resistance: Excellent resistance to corrosion, making them suitable for various environments.

- Thermal Conductivity: High thermal conductivity, ideal for heating applications.

- Formability: Easily fabricated and formed into various shapes and sizes.

- Durability: Long-lasting performance under normal operating conditions.

Chemical Composition

| Alloy | Copper (Cu) | Lead (Pb) | Iron (Fe) | Oxygen (O) | Other Elements |

|---|---|---|---|---|---|

| C10200 | 99.90% min | 0.001% max | 0.05% max | 0.02% max | – |

| C12000 | 99.90% min | 0.001% max | 0.05% max | 0.02% max | – |

| C12200 | 99.90% min | 0.001% max | 0.05% max | 0.02% max | – |

Mechanical Properties

| Property | C10200 | C12000 | C12200 |

|---|---|---|---|

| Yield Strength (ksi) | 30 | 30 | 30 |

| Tensile Strength (ksi) | 50 | 50 | 50 |

| Elongation (%) | 30 | 30 | 30 |

| Hardness (Rockwell) | B60 | B60 | B60 |

Steel Grade

While the primary focus is on copper alloys, it is essential to note that these materials are often compared to steel grades in terms of strength and application suitability. However, copper alloys generally provide superior corrosion resistance and thermal conductivity compared to steel.

Application

The seamless copper water tubes are widely used in:

- Plumbing systems

- Heating systems

- Refrigeration

- Air conditioning

- Industrial applications

Possible Alternative Grades

In addition to C10200, C12000, and C12200, other copper alloys may serve as alternatives depending on specific requirements:

- C70600: Copper-nickel alloy, known for its excellent corrosion resistance in marine environments.

- C71500: Copper-nickel alloy with enhanced strength and corrosion resistance.

- C44300: Copper-zinc alloy, suitable for applications requiring good mechanical properties and corrosion resistance.